Autonomous Maintenance

(Japanese: Jishu Hozen)

Simple Explanation

The term ‘Autonomous Maintenance’ refers to the concept in industry where the operators of machines and equipment are trained to perform some basic maintenance tasks on their machines to reduce chances of breakdown.

Autonomous Maintenance is actually a sub-concept of a bigger concept in maintenance called Total Productive Maintenance (TPM). It is a maintenance philosophy first introduced by Japan Institute of Plant Maintenance (JIPM) by Seiichi Nakajima, a Japanese maintenance consultant and teacher known as the father of TPM.

The Total Productive Maintenance (TPM) philosophy has eight pillars and “Jishu Hozen” or Autonomous Maintenance is one of those eight pillars. In order to understand the concept of Autonomous Maintenance, it is important to understand the background in which the philosophy of Total Productive Maintenance (TPM) was developed.

Let us briefly look at the background of TPM which will enable us to better understand the concept of Autonomous Maintenance.

A Brief Background of Total Productive Maintenance (TPM)

After industrial revolution, the discipline of maintenance evolved because machines that broke down during operation had to be fixed to get the production back up again.

Naturally, the very first way maintenance was conducted was primitive. If a machine broke down, a technician would come and fix it. This type of maintenance where you go and fix machines after a breakdown is called Reactive Maintenance. It was the first generation of maintenance philosophy throughout before 1950.

Over time, as industrial knowledge expanded, it was realized that Reactive Maintenance is not such a good way of doing maintenance. Engineers and technicians realized that many breakdowns can be prevented if we check machines periodically and change worn out components, like an oil filter on an engine.

The above way of maintenance evolved into the Preventive Maintenance philosophy which prevailed during the 1950s. The maintenance department developed maintenance schedules and did not sit idle until the operations department complained that a machine has broken down.

As industrial knowledge and experience expanded further, it was realized that the responsibility of maintenance is not supposed to be confined in the maintenance department. It is an organizational responsibility and other departments as well as overall organizational culture is supposed to play its part.

This latest philosophy emerged in the 1970s and is called Total Productive Maintenance (TPM).

The all-encompassing nature of TPM philosophy is evident from its eight pillars that define the philosophy:

- Focused Improvement

- Autonomous Maintenance

- Planned Maintenance

- Early Equipment Management

- Quality Maintenance

- Education and Training

- Administrative and Office Maintenance

- Safety, Health and Environment

You can see that Autonomous Maintenance is one of the eight pillars of the Total Productive Maintenance (TPM).

What’s Autonomous in Autonomous Maintenance?

As you can now understand how Autonomous Maintenance is part of a bigger picture i.e., Total Productive Maintenance (TPM) which evolved as a maintenance philosophy over the long history of industrial maintenance, let us now leave the other seven pillars and focus on Autonomous Maintenance.

Historically, the operation and maintenance departments were strictly divided such that operators did not interfere with the equipment maintenance and maintenance did not interfere with operation of equipment. Operations was supposed to report equipment issues to maintenance and maintenance was supposed to send a technician to fix it.

However, maintenance departments noticed that a wide variety of problems experienced in the equipment are because the operators are not aware of maintenance-related knowledge.

They sometimes don’t follow proper startup procedure for a machine which causes breakdown. Quite often, the fault could have been prevented if a general inspection of machine was conducted before startup. It was realized that if operators are given some basic knowledge of maintenance and more autonomy over the machines, breakdowns would be greatly reduced.

This is how Autonomous Maintenance concept was developed. In Autonomous Maintenance, operators are taught to carry out inspection of machine before startup and basic cleaning and servicing of equipment.

As time has passed by, Autonomous Maintenance has also covered first line maintenance tasks i.e., maintenance tasks which don’t need equipment disassembly, part replacement or any advanced tool or technique. For example, a simple reset of a circuit breaker.

Autonomous Maintenance Examples

Let us share some practical examples of Autonomous Maintenance.

In a process or manufacturing plant, Autonomous Maintenance can include activities such as oil levels in compressors and gearboxes, leakage inspection of pressurized gas or liquid pipes, and basic servicing and cleaning of electrical switchgear.

In Heating Ventilation and Airconditioning (HVAC) industry, Autonomous Maintenance can include activities like replacement of air filters, cleaning of evaporator and condenser coils and inspection for observing noise and vibration in HVAC units.

In a water treatment plant or pumping station, Autonomous Maintenance can include routine inspection of pumps and motors for any noise or vibration, taking current readings of motors, leakage inspection of joints in the pipeline and monitoring data of pump head and flow to detect any anomaly.

In a solar power plant, Autonomous Maintenance can include activities such as inspecting and cleaning solar panels, tightening electrical connections, topping up batteries acid and removing simple tripping of circuit breakers.

7 Steps of Implementing Autonomous Maintenance

Implementation of Autonomous Maintenance is carried out through seven steps as given under:

- Increase operator knowledge regarding equipment functionality and basic maintenance tasks.

- Initial cleaning and inspection of equipment before startup is made part of standard operating procedure.

- Train operators to learn to eliminate causes of contamination by good housekeeping of workstations.

- Set standards for lubrication and inspection to standardize work such as by developing checklists for operators to follow.

- Conduct inspection and monitoring of equipment while its running to make sure any abnormality is immediately caught by the operator.

- Standardize visual maintenance management which refers to developing visual aids such as informative posters for operators to better understand correct operating procedures and basic maintenance tasks.

- Establish continuous improvement in the system by gradually increasing the knowledge of operators and delegating more and more maintenance tasks to operations.

With this we conclude the explanation. If you found this article useful, please share this article with likeminded people.

Other Articles You May Like

brizy_dc_post_title

Learn about Autonomous Maintenance - part of Total Productive Maintenance that empowers machine operators in basic maintenance tasks.

brizy_dc_post_title

Learn what is RAMS - acronym of Reliability, Availability, Maintainability & Safety/Supportability - in industrial maintenance.

brizy_dc_post_title

We explain what is the supposed role of Maintenance Planning Department in industry. We clear misconceptions and give do's and don'ts.

brizy_dc_post_title

Explaining 6 industrial maintenance types: Preventive, Reactive, Corrective, Predictive, Proactive and Reliability Centered Maintenance.

brizy_dc_post_title

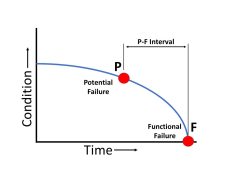

Practical aspects of PF Curve and PF Interval in maintenance & reliability explained. Learn what's the most important question in PF interval?

brizy_dc_post_title

The practical application of ABC classification of inventory for maintenance spare parts with examples from different industries.

brizy_dc_post_title

We explain the concept of Inherent Reliability - A metric used in industrial maintenance and reliability management.

brizy_dc_post_title

Intuitive explanation of Achieved Availability - Metric used in Industrial Maintenance & Reliability Management.

brizy_dc_post_title

Explaining in simple English the term Mean Time To Repair or Replace (MTTR) used in maintenance management.

brizy_dc_post_title

We explain the terms Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) in simple and practical language.

brizy_dc_post_title

We give a detailed example of calculating Overall Equipment Effectiveness (OEE) for HVAC equipment (in a story telling style).

brizy_dc_post_title

Explaining the 8 wastes of lean manufacturing (or lean production) philosophy that are applicable on maintenance management.

brizy_dc_post_title

Intuitive explanation of the difference between Total Effective Equipment Performance (TEEP) & Overall Equipment Effectiveness (OEE).

brizy_dc_post_title

We explain in layman terms what is Overall Equipment Effectiveness (OEE) - a metric maintenance teams aim to maximize in industry.

brizy_dc_post_title

We explain a useful metric that is used by maintenance managers to determine efficiency of their maintenance workforce.

brizy_dc_post_title

We explain the maintenance work order system (or work management system) used by maintenance departments in simple words.