Best Screw Extractor Sets | Application Based Top Picks

Affiliate disclosure: Handy Tool Adviser is reader supported. When you buy through our links, we receive a small commission at no additional cost to you.

Are you confused what is the best screw extractor? Have you checked different available options but are not sure what is the best easy out tool?

With so many options and competing brands available in the market, it becomes hard to choose the best screw extractor for your requirement.

In this post, we will give you our recommendations on the 2 best screw extractor sets for occasional use and the 2 best for professional use. We will discuss the pros and cons of each set that helped us determine the best option for your specific requirement.

Our top picks for occasional use will serve those people who are looking to buy a screw extractor just for one time use and keep the set if something similar ever happens again.

On the other hand, our top picks for professional use will serve those workers, contractors and DIYers who get into stuck screw trouble frequently.

1. IRWIN Screw Extractor & Drill Bit Set (10-Piece)

Our Rating: 9.1 / 10

IRWIN packs this package with 5 spiral extractor bits and 5 drill bits to make a total of 10 piece set that leaves no need for an eleventh piece. It is the best screw extractor set for occasional users providing you 5 screw extractors ranging in drill bit reference size from 5/64 inch (2mm) to 19/64 inch (7.5mm). Designed to remove broken bolts, studs, socket screws and fittings, the extractor bits are compatible with drills as well as ratchets.

There has been some negative feedback indicating the bits snapped during use, however, bits are strong and reliable for occasional use at home and DIY.

Pros

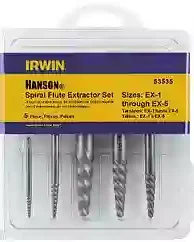

2. IRWIN Spiral Flute Screw Extractor Set (05-Piece)

Our Rating: 9.0 / 10

This small screw extractor set by IRWIN packs a lot of punch with 5 screw extractor bits ranging in drill bit reference size from 5/64 inch (2mm) to 19/64 inch (7.5mm). These extractors can be fit inside a drill bit or a ratchet, however you feel convenient.

The reason why this screw extractor set is placed second in our list and not first is that it does not include drill bits and does not come with a case for storage. Other than that, it is no less than our first recommendation in terms of utilization.

There has been some negative feedback indicating the bits snapped during use, however, bits are strong and reliable for occasional use at home and DIY.

Pros

The 2 Best Screw Extractor Sets for Professional Use

1. IRWIN Multi Spline Screw Extractor Set (25-Piece)

Our Rating: 9.4 / 10

If you are a mechanic, contractor or workshop owner that needs to have a screw extractor set for wide range of mechanical applications, this is the best screw extractor set we found for you in our market survey.

Designed for removing broken bolts, studs and screws for high torque applications, it contains 25 screw extractors ranging in size from 1/8 inch (3.175mm) to 7/8 inch (22.225mm). The extractors are made of high carbon steel that make them suitable for heavy duty applications such as extraction of bolts from engine blocks, hydraulic machinery and other industrial applications.

Positive feedbacks on strength and reliability of screw extractors were highest for this set on occasional as well as professional tough applications.

Pros

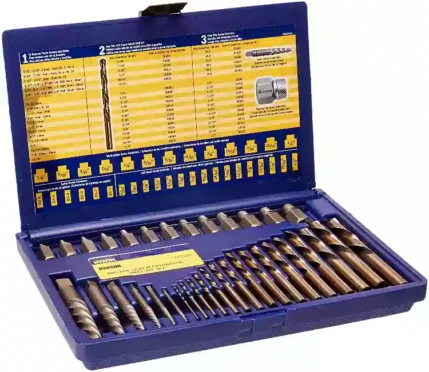

2. IRWIN Screw Extractor and Drill Bit Set (35-Piece)

Our Rating: 9.0 / 10

This 35 piece screw extractor set includes drill bits as well to make it a self sufficient package. Screw extractors made out of Cobalt range in size from 5/64" (2 mm) to 1/2" (12.7 mm) to suit varied applications.

The set contains two types of designs in screw extractors, one is a multi spline design that is more suitable for heavier applications and the other is a spiral flute design that gives a better grip over the job because of its ability to dig deeper into the job as you turn it to extract the screw.

This set is the best screw extractor set for professionals and DIYers dealing with medium duty applications.

There has been some negative feedback indicating the bits snapped during use on heavy duty application that's why its strength and reliability score is less than our first recommendation.

Pros

Best Screw Extractor Pliers - An Alternate Solution

Engineer PZ-58 Screw Extractor Pliers

Screw extractor sets are best solution for extracting stripped screws, however, they are not the only solution. A screw extractor pliers set is a very good alternate solution for everyday applications.

This screw pliers set made of high carbon steel can extract any stripped screw whose head can be gripped with its jaws. Its jaws have serrations that provide friction during the extraction procedure. If the screw head can be gripped, screw extraction is much easier with this set of pliers than a screw extractor set.

Buyer's Guide Questions

How do you extract a screw with an extractor?

Every screw extractor set comes with a small piece of paper inside the box or package that explains how to use the screw extractor set for removing stripped screws. The procedure does not vary very much as the main concept remains same that comprises following main steps,

1. First of all select a suitable screw extractor size with the help of which you will remove the stripped screw. The size of screw extractor must be smaller than the size of screw you are trying to extract for example if the stripped screw size is 5mm (nominal dia), you have to select an extractor that is less than 5mm in size. You can also check manufacturer recommendations for this step.

2. Center punch the visible head of stripped screw, broken bolt or stud that you are trying to extract. Using a center punch tool with a mallet or hammer will do the job.

3. Select a suitable drill bit size and drill a hole in the stripped screw. The drill bit size is dependent on screw extractor size. The recommended drill bit size to be used with each extractor is etched on IRWIN screw extractors that we have reviewed in our post. If you are using another brand, a chart will definitely be there for matching drill bits with screw extractors. An important tip here is to first drill a hole with a drill bit size smaller than the recommended and then enlarge/bore the same hole with recommended drill bit size. It will ensure that you drill the perfect hole.

4. Lightly tap the screw extractor into the hole you have just drilled (with IRWIN spiral flute screw extractors, you don't have to tap it. You just have to press it and rotate it counter clockwise and it will dig into the job itself).

5. Using a socket wrench, rotate the screw extractor counter clockwise. You can also use a drill for this purpose but the rotation must be reversed and speed set to lowest. If all above steps have been performed correctly, screw extractor will come out with the stripped screw

(Credit: Rockler Woodworking & Hardware - YouTube Channel)

What to look for in a screw extractor set?

You must look for the following main parameters and features when buying a screw extractor set,

Look for Nature of Your Intended Utilization

If you are not a professional, you can go for a small screw extractor set that contains 5 or maximum 10 pieces you can use for removing stripped screws, broken bolts and studs in your furniture and home appliances. The best we have recommended is IRWIN Screw Extractor & Drill Bit Set (10-Piece) and the second best is a 05 piece set. However, if you are a mechanic, contractor or DIYer running a backyard workshop, you need something more serious. You must go for larger screw extractor set that can take care of high torque applications and comprises a wide range of sizes such as IRWIN Multi Spline Screw Extractor Set (25-Piece) and IRWIN 35-Piece Screw Extractor and Drill Bit Set.

Look for Hardness & Durability

The main problem faced in screw extraction is that the extractor will break or snap because it is not hard and durable enough. Majority screw extractors are made of high carbon steel or cobalt steel, however, just reading material composition doesn't ensure hardness and durability. You must always thoroughly check the reviews of the screw extractor set and look for bad reviews that mention the screw extractor failure during use. If such reviews are not that much go for it.

Trust the customer reviews about hardness and durability more than fancy statements by brands about how they tempered the steel twice to make the material hard and durable.

Look for drill bits included in the set

Since drilling correct size hole is first step of screw extraction, go for a screw extractor set that also has the recommended drill bits to be used with screw extractors so that once the set is received, you have no worries about finding and matching the correct drill bit size with the extractor.

Drill bits are included in IRWIN Screw Extractor 10-Piece, 25-Piece and 35-Piece sets.

Look for extractor sizes etched on extractors

If you are not a frequent or professional user of screw extractors, you need to look for etched screw extractor and recommended drill bit sizes on the screw extractor bits themselves so you don't have to do any guess work. The IRWIN screw extractors we have reviewed come with this feature.

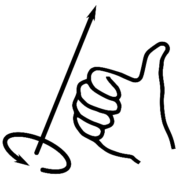

How Screw Extractors Work? - The Science Behind The Magic!

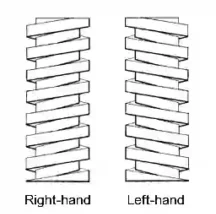

You need to understand just two main terms to comprehend how screw extractors work. These terms are 'Right Handed Thread' and 'Left Handed Thread'. Right handed threads follow the right hand rule and left handed threads follow the left hand rule. What are these threads and rules?

Right handed thread refers to the design and direction of threads machined on any conventional screw or bolt as per right hand rule such that when you curl your right hand fingers in the direction of bolt rotation, the direction of your thumb shows whether the bolt would unwind and come out of a job or wind and go deeper into the job. Right Hand Threads are conventionally used on all screws and bolts in industry and that is why the general rule is to rotate the screw counter clockwise for unwinding or un-tightening.

Left handed thread is opposite of right handed thread. The threads are machined in the opposite direction so that its tightening and un-tightening directions are reversed. It follows the left hand rule such that if you curl your left hand fingers in the direction of screw rotation, your thumb will tell the direction of its movement.

Screw extractors have left hand threads machined on them. When you rotate them counter clockwise, they tend to dig into the job as per left hand rule. As they dig deeper millimeter by millimeter, their grip gets stronger and stronger on the stud you are trying to extract because screw extractors are cone shaped and they get larger towards the top.

A point comes when the screw extractor cannot go any deeper because of the resistance being offered by the job it is digging into, but you are still applying force and trying to rotate the stripped screw so what now? Now the stripped screw itself starts to rotate inside the stuff it was stuck. As the stripped screw rotates, it starts to come out and the job gets done.

If you liked this post, please share it with someone who may benefit from it.

Other article suggestions