The Intended Role of Maintenance Planners in Industry

Affiliate Disclosure: Handy Tool Adviser is reader-supported. When you buy through links on our site, we may earn an affiliate commission at no cost to you. Read more about our affiliate association here.

In the old days of maintenance, it was just the operations department and the maintenance department. In case of any fault experienced in any of the machines in a facility, operators informed the maintenance department, who sent a technician to go and fix it.

The technician would come, check the problem, assess what tools and spare parts does he need to solve the issue and go fetch them. After arranging the necessary tools and parts, the technician would repair the machine and give it back in service.

The above state of affairs continued to work until industry came up with a better approach – the work order system (we’ve explained it here). In that work order system, there was a specific role to be played by a specific group of people. The role was Maintenance Planning and the group of people were Maintenance Planners.

It is easy to just give you a few bullets of what a maintenance planner does, however, that will not result in development of a profound understanding of the role of a maintenance planner. We would like to explain it in an intuitive way to make you realize the importance of the role in the context of evolution of industrial maintenance.

So, we were talking about the old days of maintenance that how machines and equipment were fixed back then by simple communication between the operations and maintenance departments. The reason why industry shifted towards a work order system was to document maintenance work properly.

Once you document work, you can quantify it. Once you can quantify it, you can measure it. Once you can measure it, you can manage and control it. This was the whole philosophy of the work order system. However, where does Maintenance Planning fit in this?

Understanding What Maintenance Planning is NOT!

From a layman perspective, when someone hears the term ‘Maintenance Planner’, what comes to mind is someone who plans maintenance. Someone who tells what maintenance work to do and when to do it.

Right?

Wrong!

In reality, Maintenance Planners neither deal with the “what” of work nor with the “when” of work. Maintenance Planners deal with the “how” of work.

“What” maintenance work will be executed comes from the operations department who inform about a problem or fault in equipment to the maintenance department. For example, if operators find that a certain machine is giving abnormal noise during operation, they’d raise a complaint to the maintenance department and a work request will be generated.

Or, the maintenance work could come from other persons in maintenance such as Preventive Maintenance team or Predictive Maintenance team who, during their own inspection and activity, observed something that they feel needs to be taken care of in due course of time. They would raise a work request to the maintenance department.

Therefore, what maintenance work will be executed by the maintenance workforce is not decided by Maintenance Planners. It comes from other departments or other teams.

Coming towards the other part which is deciding the “when” of maintenance, it is done by Maintenance Schedulers. They are different people than Maintenance Planners. Their job is to prioritize the tasks that will be executed in the coming week.

In between the above two i.e., work requests and maintenance scheduling, lie the role of a Maintenance Planner.

Job Scoping & Job Plan – What Maintenance Planner Primarily Does!

Maintenance Planners receive approved work requests from the maintenance manager i.e., the work requests that have been shortlisted as valid work. The reason for work request scrutiny is that sometimes multiple work requests can be generated by equipment operators for the same problem.

Once the approved work requests have been received, Maintenance Planners see what the complaint is about. They go and visit site to check the machine themselves and ascertain what is wrong with the machine and what’s needed to fix it. They don’t disassemble the machines if the fault may be hidden but they try to identify the cause of the problem.

After finding the cause of the problem, they note what tools, parts and other materials are needed to fix the problem.

Maybe a ball bearing is needed to be replaced. What size?

A gasket is leaking and needs replacement. What specifications?

Apart from above, Maintenance Planners also consider if there are any special safety precautions to be taken during the job. Maybe the work involves working at a height and therefore a safety harness is needed. Maybe the work is on high voltage equipment therefore electrical safety gloves are needed.

Maintenance Planner also notes if there is any important technical step to be taken care of in the job. For example, to beware of pressure release when working on a bad joint on a gas line even if the flow valve has been turned off.

Maintenance Planner also considers if the technician would need any literature like the electrical or plumbing drawing.

Finally, the Maintenance Planner thinks of all the steps involved in the repair job and estimates the time duration it will take to perform the job.

The whole process of visiting the site and examining all of the above is known as Job Scoping. The standard format over which the Maintenance Planner records all of the above in the relevant boxes is called a Job Plan or Job Package.

Therefore, the primary work of a Maintenance Planner is preparing Job Plan after Job Scoping.

It is important to explain here that experienced Maintenance Planners will not need to visit site for all work requests. They would know the problem without having to visit the site, especially for similar complaints.

Creating ‘Ready Work’

The second work of Maintenance Planners is to coordinate with the spare parts store to check the availability of spare parts needed to fix the machine. The Job Plan will not be moved to the next stage unless availability of all tools, parts and materials has been confirmed.

When the above availability is confirmed, the Job Plan (or the work order) is said to become Ready Work. It means that work is ready to be executed because everything needed to do the work is available.

This Ready Work is then sent to the Maintenance Scheduler so he can include it in his prioritizing process.

Trusting Technicians & Avoiding Micro-management in Maintenance Planning

Creating of a Job Plan is not the same as creation of a standard procedure listing each and every step needed in the maintenance work.

The role of Maintenance Planner is to cut the time the technician will spend in figuring out the problem and arranging all tools and parts himself. However, Maintenance Planners are not supposed to dictate the maintenance work and suck the life out of the technician.

Maintenance technicians are skilled people and they know how to disassemble, reassemble and replace parts on a machine. It is not like they are looking forward to get that information from the Maintenance Planner.

What the Maintenance Planner is there to do is to allow the maintenance technician to become more efficient by informing him of all the catches he can expect in a job. Maintenance Planners make sure that technicians approach the job fully prepared so they spend more time in hands-on work than gathering tools and parts.

Who Qualifies as a Maintenance Planner?

It would not be hard to guess that the work expected from the Maintenance Planners cannot be performed by a novice. How would a newbie know what’s the cause of fault in a machine? What tools and parts may be needed to fix it?

Of course, it would take an experienced technician or maintenance supervisor who has had hands-on experience in fixing equipment to create Job Plans. Therefore, maintenance supervisors are generally the first people to be considered for filling a vacant post of a Maintenance Planner in any maintenance organization (or department).

Resisting the Temptation of Sending Maintenance Planners to Fix Stuff

Since Maintenance Planners are experienced crafts themselves, there is a tendency in maintenance departments to occasionally involve them in maintenance work under pressure. It is because they know how to get the work done. However, it is a bad practice.

The reason why Maintenance Planner role has been developed in industry is to focus on future work and not get busy with the present work.

Maintenance Planners are supposed to keep maintenance ahead of the game. They are supposed to figure out the “how” of work before the work is assigned to a technician. In this way, the back and forth thought process and coordination needed in figuring out the “how” of work has already been taken care of ahead of time before the job execution time arrives.

In this sense, the sole purpose of Maintenance Planners is to improve what’s called the Wrench Time i.e., the time spend by technicians on doing hands-on maintenance work instead of wasting time to get parts and tools.

Maintenance Planning Job isn’t Complete Until the Job is Done!

The job of a Maintenance Planner isn’t complete yet.

After the technician has actually performed the job, he submits the completed work order with his feedback which reaches the Maintenance Planners.

This is one of the most important stage of work for Maintenance Planners.

They check the feedback of the technician to ascertain how well did they plan the work?

Did the technician actually find something else other than what they had envisaged?

Did the job take more or less time than they estimated?

Did the technician point out anything that he felt should’ve been informed him earlier to better prepare for the job?

Answer to all these questions are examined by the Maintenance Planners. They learn from the shortcomings identified in their Job Plans to make them better the next time.

Maintenance Planners meticulously document all Work Orders in a very organized way. The documentation management is aimed at making maintenance planning better over time.

With this, we conclude our discussion here. We hope you’ve found this article insightful. If you have, do share it with likeminded people.

Other Articles You May Like

brizy_dc_post_title

Learn about Autonomous Maintenance - part of Total Productive Maintenance that empowers machine operators in basic maintenance tasks.

brizy_dc_post_title

Learn what is RAMS - acronym of Reliability, Availability, Maintainability & Safety/Supportability - in industrial maintenance.

brizy_dc_post_title

We explain what is the supposed role of Maintenance Planning Department in industry. We clear misconceptions and give do's and don'ts.

brizy_dc_post_title

Explaining 6 industrial maintenance types: Preventive, Reactive, Corrective, Predictive, Proactive and Reliability Centered Maintenance.

brizy_dc_post_title

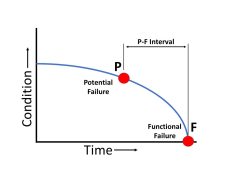

Practical aspects of PF Curve and PF Interval in maintenance & reliability explained. Learn what's the most important question in PF interval?

brizy_dc_post_title

The practical application of ABC classification of inventory for maintenance spare parts with examples from different industries.

brizy_dc_post_title

We explain the concept of Inherent Reliability - A metric used in industrial maintenance and reliability management.

brizy_dc_post_title

Intuitive explanation of Achieved Availability - Metric used in Industrial Maintenance & Reliability Management.

brizy_dc_post_title

Explaining in simple English the term Mean Time To Repair or Replace (MTTR) used in maintenance management.

brizy_dc_post_title

We explain the terms Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) in simple and practical language.

brizy_dc_post_title

We give a detailed example of calculating Overall Equipment Effectiveness (OEE) for HVAC equipment (in a story telling style).

brizy_dc_post_title

Explaining the 8 wastes of lean manufacturing (or lean production) philosophy that are applicable on maintenance management.

brizy_dc_post_title

Intuitive explanation of the difference between Total Effective Equipment Performance (TEEP) & Overall Equipment Effectiveness (OEE).

brizy_dc_post_title

We explain in layman terms what is Overall Equipment Effectiveness (OEE) - a metric maintenance teams aim to maximize in industry.

brizy_dc_post_title

We explain a useful metric that is used by maintenance managers to determine efficiency of their maintenance workforce.

brizy_dc_post_title

We explain the maintenance work order system (or work management system) used by maintenance departments in simple words.