Maintenance Work Order System (or Work Management System) Explained [FOR NOOBS]

In this article, we are going to introduce the concept of work order system in maintenance (also known as work management system), which is widely used by maintenance departments of power plants and process industries around the world.

We are going to keep the explanations very simple and easy to understand as if the reader does not know anything about the topic.

How Maintenance was carried out before Work Order System?

In order to understand the maintenance work order system, we first need to understand how maintenance was carried out before the modern work order system came into existence.

Before work order system, maintenance departments had to rely on a team of people in constant communication with each other (generally via telephonic calls) to inform each other about the issues arriving in a plant (or facility). The operations team would call maintenance personnel whenever a breakdown would occur or something started giving noise or any other unusual observation was made.

Maintenance technicians would reach the site, check the problem and fix it. In case any part or any special tool was required to fix the issue, they would go to the tools room or the spare parts store and get the items issued. In case of emergencies or complex issues they contacted the engineering department for support.

Why the Work Order System came into existence?

As industry developed and plants became more and more complex, the need for devising a better system of managing work became more and more important. The main purpose of work order system was to streamline things and make maintenance management more orderly and organized.

If the work order system can be expressed in a single word, it is “documentation”.

Documentation allows tracking of work which allows the maintenance management to know exactly what’s happening and allows the department to manage its maintenance workforce more efficiently. Work order systems reduced confusion, eliminated waste of time, money and efforts by avoiding unnecessary calls between different departments.

How Work Order System works?

Imagine a power plant where boilers, pumps, heat exchangers and steam turbines are connected through a complex network of pipelines and valves. There is an operations department where operations personnel are responsible for turning things on and off and keeping a check that everything is running smoothly.

There is a maintenance department which is responsible for fixing any problems that the operations department reports. Maintenance department has a team of mechanics, technicians and other skilled labor that repairs equipment.

Work Request – The First Step

Work order system starts with a Work Request. A work request is a form (generally single pager) over which operations department writes its issues.

For example, maybe a steam valve is leaking and needs to be replaced or the pressure in a pump has decreased and it needs to be fixed. A work request form will be filled by the operations team and submitted to the maintenance department.

It is called work request because a user is requesting maintenance department to work on a problem.

Approval of the Work Request = Work Order

The maintenance department has a maintenance manager. He will check the nature of complaint in the work request and decide whether it is a valid complaint or not.

Maybe same complaint had been received from previous operations shift and has already been processed upon which maintenance manager will reject the work request.

Or maybe, the faulty pump had already been checked by maintenance team three days ago and it was decided that this pump will be replaced next week. Until then, any non-serious maintenance work is deemed uneconomical, something technically referred to as “Run to Failure” i.e., allowing a machine or component to run until failure deliberately.

If the work request is deemed valid by the maintenance manager, he will approve it. Once approved, work request becomes a work order.

Creation of Job Plan by Maintenance Planner

After maintenance manager has approved the work request, it goes to someone known as a Maintenance Planner.

While it may appear that maintenance planner will plan when the work will be done, it is not the case. The when is decided by Maintenance Scheduler, which we will discuss later.

Maintenance Planner produces what is called a Job Plan.

Job Plan is a document (or section of a Work Order document) that communicates with the maintenance technicians. It tells them all the tools, spare part and other materials they need to carry with them to the jobsite. It also tells them the basic steps involved in the repair job along with the estimated time of repair. It also highlights any special safety measures needed to be considered during the job.

Simply put, job plan is a document that describes what needs to be done and what will be needed to do it.

To produce the job plan, the planner pays a visit to the site where the problem is reported and conducts a preliminary inspection of the issue. It is technically called Job Scoping because the planner is ascertaining scope of work. He does not disassemble anything but checks the nature of the problem and what is needed to be done to fix it.

Maintenance Planners are experienced craftsmen (generally former maintenance supervisors) due to which they are very able to assess what’s the problem and how to fix it. However, they don’t do the fixing themselves. They just produce the job plans.

Planners are also responsible for coordinating with the spare parts store for ensuring availability of required spare parts and materials needed in the job for which they are producing the job plan.

Once job plan is created and all materials and parts are made available, the job is said to be ready or Ready Work. What is it ready for? – Execution.

In a maintenance department running efficiently, maintenance planners will be producing job plans worth more than 2 weeks of work.

Scheduling Work

After maintenance planners have completed their work and Ready Work has been produced, Maintenance Schedulers carry on the torch from there.

Maintenance schedulers are officials responsible for deciding the when of work in a maintenance department.

They assess the priority of work and select a week’s worth of work from all the job plans they receive from the planners. In doing so, they also look at the available manpower (of technicians and skilled labor) to ascertain how much work can be assigned for a given week.

For instance, if some technicians are on vacation, maintenance schedulers are informed about it and they take it into consideration when assigning a week’s worth of work.

The amount of work that maintenance schedulers assign for a week becomes the workload (or target) for maintenance supervisors for that week. They are able to do that because Planners have already mentioned estimated time of job on each Job Plan.

Maintenance schedulers neither assign jobs to technicians nor mention the exact date and time of each individual job (unless in special cases). They simply select X amount of Job Plans worth Y cumulative hours to be completed in the coming week.

Maintenance Supervisor and Distribution of Work

Maintenance supervisors receive the week’s worth of work from maintenance schedulers and assign individual work to individual technicians and mechanics.

It is the maintenance supervisor who controls what repairs will the technicians perform and when will they perform it. Maintenance supervisors also coordinate with operations supervisors or operations coordinator to free up equipment for their technicians when work is to be performed.

Maintenance supervisors keep afoot in the plant guiding as well as counter-checking the work of labor to make sure work is performed using best practices. Maintenance supervisors also check the quality of work performed by maintenance technicians.

Work Execution by Technician

On receipt of the Job Plan from the maintenance supervisor, the maintenance technician receives the specified tools and spare parts needed for executing the job from the tool room and spare parts store respectively.

He reads the job plan to understand whatever the maintenance planner has tried to explain and convey on it. However, it is not like he keeps the job plan in front of him and execute the job step by step following the job plan.

After executing the work, technician submits a written completion report. If the technician feels that some important points regarding the job were not found on the job plan, he provides his feedback in writing as well.

Work Execution Report & Feedback of Technician

The completion report and feedback are submitted back to the maintenance supervisor who submits it to the maintenance scheduler.

Maintenance scheduler acknowledges completion of work and sends any feedback regarding job plans to the planners.

Planners use the feedback to improve future job plans. In fact, as maintenance department matures, planners don’t need to make new plans as most work in a plant is repeatable and older job plans can be used as templates for new ones.

In a Nutshell

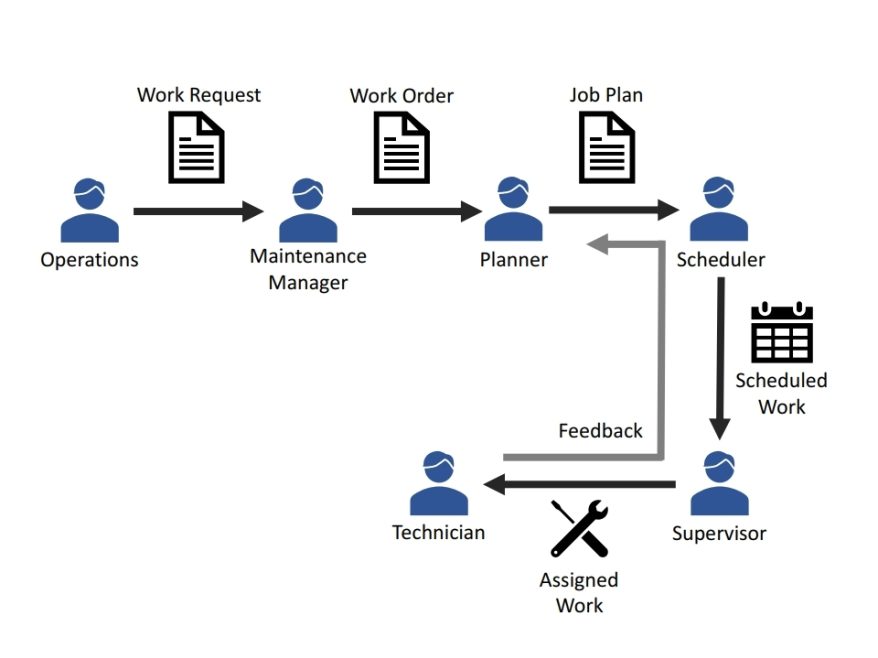

The work request generated by operations gets converted into work order after getting approved by maintenance manager. A Job Plan is created by maintenance planner and is forwarded to maintenance scheduler who prioritizes a week’s worth of work for the plant. This week’s worth of work is received by maintenance supervisor who is responsible for daily distribution of work to technicians and craftsmen. They execute the job and give feedback for completing the cycle.

All this work flow can either be done in hard form through papers, forms and filing. Or it can be done through what is called a Computerized Maintenance Management System (CMMS). Either way, the basic flow of work in a work order system will more or less be the same as explained in this article.

References & Further Reading

The Maintenance Work Order Management System is a broad topic. Out intent (in this article) was to introduce its basics in a manner that a layman would understand. If you want to develop further knowledge of the subject matter, we recommend going through the following resources:

- Maintenance Planning and Scheduling Handbook by Richard Palmer, 4th Edition, 2019, McGraw-Hill Education, New York (Link). It is considered one of the best resources for learning about maintenance management (including the work order management system).

- Maintenance & Reliability Best Practices by Ramesh Gulati (with contributions by Ricky Smith), ISBN 978-0-8311-3311-5 (Link).

If you liked this post, please share it with someone who may benefit from it.

Other article suggestions