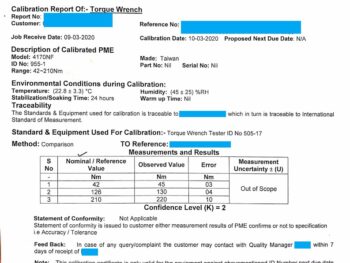

Explaining the Difference Between Milling and Welding

While engineers and tradesmen understand the difference between different manufacturing processes, a layman can find it difficult to understand the same. One of the confusions that a layman may have in this regard is to explain the difference between milling and welding – two different manufacturing processes used in industry and workshops to make stuff.

To make it simple just remember that,

"Milling is about removing material and welding is about adding material"

Milling and welding are two completely different manufacturing processes. They are so different that by the end of this article, you’d say how could anyone have any confusion in such a simple thing.

Milling

Milling is technically defined in the engineering world as under:

“Milling is a machining operation in which a workpart is fed past a rotating cylindrical tool with multiple cutting edges”

(Fundamentals of Modern Manufacturing: Materials, Processes and Systems by Mikel P. Groover, 4th Edition)

We admit the above definition is not easily digestible. So let us make it easy.

In manufacturing, whenever you want to make a shape out of something, you start with a big lump of material and remove material from places which would convert it into the desired shape of the finished object. It is very much like a sculptor carves out a face in stone. Milling is conceptually similar except for the process is mechanical and involves special machinery.

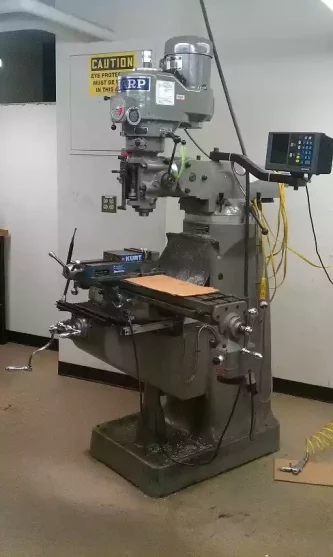

The machine that carries out milling is called a milling machine. How does a milling machine look like?

A Milling Machine

(Image Credit: BUEngineer via Wikimedia Commons)

How the machine looks doesn’t really clearly explain what it does and how it does it, right?

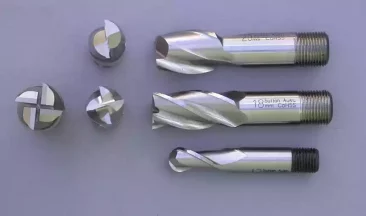

To boil it down to the basics, milling machine has what is called a Milling Cutter. It is basically a rotating cutter and can have different types (check illustration below).

Different Types of Milling Cutters

(Image Credit: Graibeard via Wikimedia Commons)

The Milling Cutter keeps rotating by a powerful electric motor. Any surface that comes into contact with this rotating cutter gets its material removed. The milling machine is nothing but a rig designed to control this material removal to the smallest millimeter.

It is designed to move the Milling Cutter or the job (the lump of material being worked on) in a way that material is removed from the intended places so as to result into the final intended shape of the finished object or product. Check the illustration below,

Notice how the Milling Cutter moves over the surface of the job to remove material in a predefined shape and amount

(Video Credit: YouTube Channel “Owl’s Garage”)

Simply put, milling is a process of removing material from a workpiece using a special machine/rig to convert it into a desired geometry. With milling, you start with a block of metal and use the milling machine to carve out the intended shape of a finished object.

Welding

Let us explain welding process in layman terms.

Welding is the process of fusing two metals together.

This fusion is made possible by heating the two metals to a very high temperature and joining them together with a filler metal that acts kind of like a glue. Heat causes them to soften and when they solidify, the joint is made permanent. This is the simplest way of explaining welding.

The above mentioned heating may be accomplished by a burning gas (called gas welding) or by electricity (called electric arc welding). For each type, there is a special piece of machinery called a welding plant. Welding is performed by hand by a skilled person called a welder.

An Electric Welding Plant

(Image Credit: Amazon)

In welding, the welder joins the two parts of metal to be fused together. He then uses the welding stick as a guide to his welding action. The welding stick is accompanied by a welding torch (in case of gas welding) or an electrical clamp (in case of electric welding). Check the illustrations below.

Tungsten Inert Gas (TIG) Welding in Action – A Type of Gas Welding

(Video Credit: YouTube Channel “weldingtipsandtricks”)

Electrical Welding

(Video Credit: YouTube Channel “Stock Welder”)

Summarizing the Differences Between Milling and Welding

- Milling is a machining process and welding is a jointing process.

- Milling removes material and welding joins material.

- Milling does its job by cutting action and welding does its job by fusion action.

- Milling is used for creating parts and welding is used for joining parts.

- Milling machine is a heavy piece of equipment that cannot be loaded on your truck and taken to the jobsite. Milling is a process used in factories and manufacturing facilities. On the other hand, welding is often performed on jobsites using portable welding plants.

- Milling is a relatively modern manufacturing process whereas welding origins are traceable to ancient Egypt (archeologists have discovered forge welded articles of bronze from pyramids of Egypt).

If you liked this article, please don't forget to share it with like minded people.

Other suggested articles