MTBF & MTTF – Simple English Explanation

The terms MTBF and MTTF are commonly used in maintenance departments to express average time of some troublesome event happening in the equipment.

While you can grab any technical handbook to learn the formulas of above terms, we have written this article with the intent of breaking it down into simple English.

The two terms we are discussing today include:

1. MTBF (Mean Time Between Failures)

2. MTTF (Mean Time To Failure)

Now let us explain each of the above terms one by one.

MTBF (Mean Time Between Failures)

It is the average time you would expect a machine to run smoothly before it causes trouble for the operation or maintenance team.

”Failure” here is more than what meets the eye.

In the context of this term, failure doesn’t necessarily mean that the machine breaks down completely and is unable to run. Failure means that it has failed to perform up to the requirement.

For example, if a pump is required to produce a flow rate of 100 GPM to fulfill requirements of a certain process, it would be considered a failure if its flow rate drops to 90 GPM. Then the maintenance team will have to check what’s wrong with the pump.

In order for the term MTBF to work, it is a prerequisite that the company has decided what would be deemed as a failure of the machine? Otherwise, failure would be considered only when the machine breaks down and stops running altogether.

If you are considering a pump in your home, failure isn’t so sophisticated. It’s simple. When the pump stops working, it is a failure. You are not concerned if a few GPMs have been lost by your pump.

However, in industries, failure is sophisticated because machines make money for the company. If a machine’s performance drops (even if it remains running), it could mean decrease in production. Consequently, a decrease in profits.

So, where do you get the MTBF of a machine from?

You get it from the historical records of the maintenance department. You ask the clerk to bring you the maintenance logbooks of (say) one year and check how many times the pump failed.

Let’s say you find that it failed 2 times. First time, its flow rate dropped for which its impeller had to be replaced. The second time, its pressure dropped for which its outlet valve had to be replaced.

Since the pump failed twice in 12 months, what is its Mean Time Between Failures? – six months.

Even if actually, the two failures might have been experienced just 2 months apart, when you average it out, it becomes six months. Had the pump failed 4 times in one year, its Mean Time Between Failures (MTBF) would have been 3 months.

So, what’s the point of calculating the MTBF?

It is calculated to express the reliability of a machine. It sorts of predicts the future.

If a wrapping machine in a packaging factory has an MTBF of 30 days, it means you can expect it to cause trouble every month which means 12 times a year.

Do you want trouble 12 times a year? – Not if you can do something about it.

So, what do you do?

You try to find ways to make it last longer by maintaining it better. You dig the data to find a trend or a common culprit for multiple issues, maybe a hidden misalignment somewhere.

Or if you arrive to the conclusion that the problem is inherent in the machine, you simply try to modify it or any of its component to see if things could get better.

If you’ve been successful, the next year’s MTBF will clearly show your achievement. Maybe, its MTBF will increase to 60 days.

So, by calculating MTBF, the maintenance department is also able to gauge the efficiency of the maintenance work. The ideal condition that every maintenance department wants is zero breakdowns.

Mean Time Between Failures (MTBF) is a metric that looks at a machine’s past to predict its future reliability. It allows you to quantify the reliability so maintenance departments have something tangible to work at.

Over time, MTBF tracks improvement or degradation of a machine’s reliability and prompts the maintenance department to do something about it.

MTTF (Mean Time To Failure)

If you’ve clearly understood what MTBF is, understanding MTTF is no problem.

First, just like failure had a special meaning in the context of MTBF, same goes for MTTF i.e., failure is when the machine doesn’t work up to the required level.

However, Mean Time Between Failures (MTBF) is for things that are repairable while Mean Time To Failure (MTTF) is for things that are not repairable. Once they fail, they are replaced.

So, for example, if a roller bearing in a machine starts producing noise and vibration, it is obvious it has failed because as per the special definition of failure, you won’t wait for the bearing to completely jam up.

What would you do when the bearing fails?

Would you repair it or replace it? – Of course, you will have to replace it because bearings are not repairable.

So, let’s say the bearing you just replaced had been in service for 100 days. It means that it took the bearing 100 days To Fail.

The new bearing you installed survived 200 days. It means it took the new bearing 200 days To Fail.

So, now when you install a new bearing again, you can expect a Mean Time of 150 days To Failure of the new bearing. This is simply the Mean Time To Failure (MTTF).

Just like Mean Time Between Failures (MTBF) expresses reliability of machines, Mean Time To Failure (MTTF) expresses reliability of parts and components.

MTBF vs. MTTF – The Most Important Differences to Remember

Now that we’ve explained both the MTBF and MTTF individually, let us understand the differences between them from a practical and field-experience perspective.

MTBF is for Machines & MTTF is for Parts

Since machines are repairable and parts are replaceable, Mean Time Between Failure (MTBF) is generally associated with machines while Mean Time To Failure (MTTF) is associated with parts.*

If a part or machine component is repairable then of course MTBF will be applicable on it, however, generally that is not the case.

If we take a pump’s example, the reliability of the pump will be expressed by MTBF while the reliability of its bearings, shaft, rubber seals and fasteners will be expressed by MTTF.

From, above it is easy to understand that if a pump is made up of reliable components, its own reliability (as a whole machine) will definitely be good. It means that if MTTF of pump’s component is high, its MTBF will likely be high as well (high values of MTBF and MTTF are good because they tell us that the time to next failure is large).

MTBF is Calculated & MTTF is Given by Manufacturer

Since Mean Time Between Failures (MTBF) is linked with the repair of the machine, its value tends to hint towards the repair job and the people repairing it. Hence, it is calculated by maintenance departments who repair the machines.

The maintenance department keeps history of repair jobs and all failures experienced in the equipment, and calculates the Mean Time Between Failures (MTBF) based on its organizational data. From there, it tries to improve its maintenance so that MTBF could be improved.

However, the maintenance department doesn’t repair the ball bearing of a pump. It installs a new one when the old one fails. So, when the new bearing fails, is it the maintenance people who are responsible?

Of course, No (unless the bearing wasn’t installed correctly).

So, who is responsible? – the people who made it i.e., the manufacturer of the ball bearing, or the people who assembled it into a machine i.e., the manufacturer of the pump in which the ball bearing is used.

Mean Time To Failure (MTTF) is therefore linked with the manufacturing of the part or component, or its selection by another manufacturer into its machine.

A high or low MTTF hints towards how well has the part been manufactured or how good was the judgement of machine’s manufacturer to select that part for its machine.

Manufacturers generally find the MTTF of the parts and components they manufacture by testing their parts in their own engineering facilities or by collecting data from clients they sell their parts to. Either way, the maintenance department generally has little to do with a good or poor MTTF.

However, it is not like the maintenance department cannot calculate and maintain data of MTTF of the machine components. It can be useful for learning if a component needs redesign to improve the overall machine reliability.

For example, if a bearing keeps failing, maybe maintenance or engineering department can replace it with a bearing having different specifications to see if it may last longer.

Similarly, it is not a strict rule that manufacturers won’t maintain the MTBF data of the equipment. Manufacturers can collect that data from their clients and give feedback to their design engineering teams so they may improve the reliability of machines they manufacture.

Uses of MTBF & MTTF

- Quantify improvement in maintenance of equipment: An increasing MTBF would express improvement in maintenance.

- Deciding maintenance schedule: Maintenance department can arrange important inspections and checks before the next probable failure.

- Forecasting demand of spare parts: Supply chains can decide inventories and order parts by taking help from MTTF values of parts.

- Exploring redesign and equipment modification opportunities: For instance, if a machine component has low MTTF, you may replace it with a better alternative to improve machine reliability.

- Deciding what warranty period to offer for parts (by manufacturers): As long as the manufacturer gives warranty within MTTF, it remains in financial safe zone.

With this, we conclude our explanation. We hope this article has been insightful for you and would request that you share it with at least one like-minded person who you think will benefit from this article.

Other Articles You May Like

brizy_dc_post_title

Learn about Autonomous Maintenance - part of Total Productive Maintenance that empowers machine operators in basic maintenance tasks.

brizy_dc_post_title

Learn what is RAMS - acronym of Reliability, Availability, Maintainability & Safety/Supportability - in industrial maintenance.

brizy_dc_post_title

We explain what is the supposed role of Maintenance Planning Department in industry. We clear misconceptions and give do's and don'ts.

brizy_dc_post_title

Explaining 6 industrial maintenance types: Preventive, Reactive, Corrective, Predictive, Proactive and Reliability Centered Maintenance.

brizy_dc_post_title

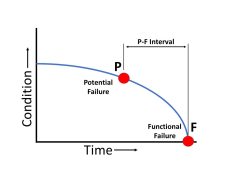

Practical aspects of PF Curve and PF Interval in maintenance & reliability explained. Learn what's the most important question in PF interval?

brizy_dc_post_title

The practical application of ABC classification of inventory for maintenance spare parts with examples from different industries.

brizy_dc_post_title

We explain the concept of Inherent Reliability - A metric used in industrial maintenance and reliability management.

brizy_dc_post_title

Intuitive explanation of Achieved Availability - Metric used in Industrial Maintenance & Reliability Management.

brizy_dc_post_title

Explaining in simple English the term Mean Time To Repair or Replace (MTTR) used in maintenance management.

brizy_dc_post_title

We explain the terms Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) in simple and practical language.

brizy_dc_post_title

We give a detailed example of calculating Overall Equipment Effectiveness (OEE) for HVAC equipment (in a story telling style).

brizy_dc_post_title

Explaining the 8 wastes of lean manufacturing (or lean production) philosophy that are applicable on maintenance management.

brizy_dc_post_title

Intuitive explanation of the difference between Total Effective Equipment Performance (TEEP) & Overall Equipment Effectiveness (OEE).

brizy_dc_post_title

We explain in layman terms what is Overall Equipment Effectiveness (OEE) - a metric maintenance teams aim to maximize in industry.

brizy_dc_post_title

We explain a useful metric that is used by maintenance managers to determine efficiency of their maintenance workforce.

brizy_dc_post_title

We explain the maintenance work order system (or work management system) used by maintenance departments in simple words.