RAMS Assessment

[Reliability, Availability, Maintainability, Safety or Supportability]

What is it? What’s its Purpose? How it’s done? Who does it?

RAMS assessment is a well-known term in the field of reliability engineering and management. It is the acronym of Reliability, Availability, Maintainability and Safety. However, some literature also defines the last ‘S’ as ‘Supportability’ – a matter we will discuss shortly.

RAMS Assessment is an advanced term of RAM Assessment which is the earlier basic version of the concept that excludes the last ‘S’ and focuses mainly on the first three components. In order to explain the topic intuitively, we’ll start with the original RAM concept and introduce the ‘S’ later.

RAM Assessment (Reliability, Availability, Maintainability)

RAM assessment evolved in industrial maintenance after reliability engineering and reliability management gained awareness. RAM assessment covered the three basic concepts and metrices that have a central role in the field of reliability engineering.

Let us first briefly introduce the three components of RAM. We won’t go into the formulas and equations because discussing each of the components is an article in itself and our purpose from this article is to explain RAMS.

The first component of RAM is Reliability which is a measure of the ability of a system or product to perform its intended functions without failure over a specified period of time under specific conditions. It is generally expressed as a percentage probability, and higher reliability indicates a low probability of failure of the machine.

One of the key metrics associated with reliability is Mean Time Between Failures (MTBF). It is simply the average time duration a machine runs (or is expected to run) before it experiences a failure for which a maintenance intervention is needed.

The second component of RAM is Availability which is a measure of uptime and downtime of equipment. Availability will be high when there are less breakdowns and machine remained running for most of the time it was required to run. Availability will be low if machine experienced breakdowns causing interruption in operations.

The key metrics associated with availability are uptime and downtime (including both scheduled and unscheduled downtime). A high uptime and low downtime gives an ideal availability percentage.

The third component of RAM is Maintainability. It is a measure of how easy it is to recover a machine from breakdown to get it back into service. It is dependent on the design of the machine.

The key metric associated with maintainability is Mean Time To Repair (MTTR). It is the average time it takes (or is expected to take) for the maintenance team to repair a machine and get it back running again.

Machines that are designed in a way that its disassembly takes too much time or that it is hard to access replaceable parts will have high MTTR resulting in a poor value of maintainability.

In the light of each of the three components of RAM described above, RAM Assessment is the assessment of an industrial facility or plant with regards to the current state of Reliability, Availability and Maintainability as well as the things needed to be done to improve it.

Two Schools of Thought in ‘S’ of RAMS (Safety vs. Supportability)

As we discussed at the start of the article that RAMS is an evolution of RAM. The last ‘S’ of RAMS is predominantly taken to represent ‘Safety’. However, another school of thought takes it as ‘Supportability’. Let us discuss both aspects.

The Safety aspect is easy to understand. In RAMS assessment, Safety refers to assessing the plant with respect to compliance with safety standards, regulations, and best practices. This involves identifying potential safety hazards, evaluating safety measures and controls, and providing recommendations for improvement.

Supportability refers to ability of a system or product to be effectively supported throughout its lifecycle to sustain the desired level of performance and availability. But what is this support in the form of?

One of the main aspects of ‘supportability’ is the logistical and supply chain support for ready availability of spare parts and other critical supplies needed to maintain a high uptime of equipment.

Supportability analysis asks whether or not a robust logistical system and supply chain management system is in place or not to ensure that the spare parts and supplies needed by the maintenance organization reach site in an ideal time.

Other aspects of supportability can include the systems in place for training of maintenance personnel for the purpose of developing expertise in equipment maintenance and the documentation system in place for properly recording and logging all maintenance and operational events of a machine so that robust analysis of facts could be performed.

Basically, everything that improves the preparedness for repairing and maintaining equipment falls under ‘supportability’ analysis part of RAMS.

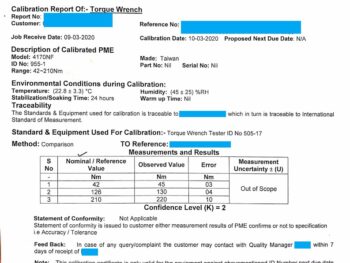

RAMS Report

The outcome of a RAMS assessment is a RAMS report. A typical RAMS report is a comprehensive document that provides an overview of the performance and status of an industrial facility or plant in terms of its RAMS characteristics (or components).

The specific contents and format of a RAMS report may vary depending on various factors but it generally covers the following main aspects:

- RAMS Performance Summary: The report presents a summary of the RAMS performance, typically in the form of tables, charts, or other graphical representations. It may include relevant metrics such as existing Uptime, Downtime, Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR) and the percentages of availability of equipment in the plant.

- Reliability Analysis: The report provides details on the reliability analysis conducted, including the methodology used, assumptions made, data sources, and results. It may include information on failure modes and their causes, reliability prediction, failure data analysis, and recommendations for improving system reliability.

- Availability Analysis: The report presents the availability analysis including the methodology used, availability calculations and the factors affecting availability such as downtime, repair time, spare parts availability, and recommendations for improving availability.

- Maintainability Analysis: The report discusses details of the maintainability analysis including the maintainability metrics such as Mean Time To Repair (MTTR), maintenance procedures, and recommendations for improving maintainability.

- Safety Analysis: The report includes details on the safety analysis conducted, including hazard identification, risk assessment, risk mitigation and recommendations for improving safety of operation and maintenance of equipment.

- RAMS Management: The report addresses management aspects, including RAMS action plans, RAMS goals, monitoring and reporting systems on RAMS performance, and any actions taken or planned to continually monitor and improve RAMS characteristics of the industrial facility.

The Role of RAMS Engineer

The importance of carrying out RAMS assessment and keep a continuous check on RAMS characteristics in an industrial facility or plant has given rise to dedicated jobs, most prominently RAMS engineer.

A RAMS engineer focuses only on RAMS projects and tasks. He/She does not get involved in maintenance and typical engineering functions but works under a reliability task force.

RAMS engineers develop RAMS targets, strategies and action plans. They execute hazard analyses; conduct RAM characteristics prediction analyses and also document and communicate results of technical data to internal departments and external customers.

With this, we conclude our explanation. If you liked our article, do share it with likeminded people.

If you liked this post, please share it with someone who may benefit from it.

Other article suggestions