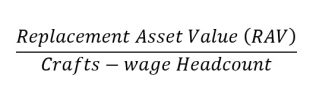

How Much Maintenance Manpower Does an Efficient Plant Need?

Ratio of RAV to Craft-wage Headcount: A Useful Metric to Understand

Determining the number of manpower needed to maintain a plant or a facility is an important part of maintaining operational efficiency in any industrial plant or facility. It is essential to ensure that there are enough maintenance labor available to carry out the necessary tasks and duties in order to keep the facility running smoothly.

Having the right amount of staff is essential in avoiding unnecessary costs due to overstaffing. By accurately estimating the number of personnel required for a particular plant or facility, businesses can save money while ensuring that their operations remain efficient.

However, the million dollar question remains - how does a maintenance manager determine what’s the ideal number of mechanics, technicians and other skilled and semi-skilled maintenance labor needed to carry out maintenance efficiently?

One metric that is used for answering the above question is known as “RAV to Craftsmen Headcount” i.e., the ratio of Replacement Asset Value (RAV) to Craftsmen Headcount.

Craft-wage Headcount

Let us first explain the denominator of the metric presented above as its explanation will be short and simple.

The term “craft-wage” commonly refers to crafts labor that have hourly wage rates defined by law in different countries. They include craftsmen that execute the hands-on work for example mechanics, welders, technicians and pipefitters in an industrial plant or painters, electricians and plumbers in facility management.

What’s important to understand that maintenance supervisors and maintenance managers are not included in craft-wage headcount because they don’t work on craft-wage rates.

The reason why craft-wage headcount is taken in the metric instead of taking (say) total number of all maintenance employees is that the inefficiency commonly lies in not effectively utilizing the manpower that is doing the hands-on work.

Furthermore, it is the craft-wage employees that make up the bulk of the ‘number’ of maintenance persons a department has.

Replacement Asset Value (RAV)

Simply put, it is the value (in USD or whatever currency you are working in) for replacing the asset being maintained.

Before explaining it further, it is important to mention some other common terminologies used in industry and literature for RAV. These include Estimated Value of Replacement (ERV) and Plant Replacement Value (PRV).

What is an asset in this context?

It is the equipment and machinery being maintained. In a thermal power plant, the assets will be the boiler, steam turbine, pumps, pressure valves and all other plant equipment. In a food packaging plant, the assets will be the conveyor system, mixing and packing machines and all allied instrumentation and control devices.

It is important to emphasize that you wouldn’t include the entire plant equipment in this metric if you are working on benchmarking a particular maintenance sub-section.

For example, in a large steel mill complex, there could be multiple maintenance departments responsible for a specific section (or area) of the plant. If this whole working has to be applied on one of the many maintenance departments, only assets maintained by that particular maintenance department will be taken into account and not the whole plant.

What is the Replacement Value in this context?

Let us first explain what replacement asset value is not. It is not the book value of the assets. Therefore, you cannot get it from the accounting department of the plant by simply asking them what’s the value of the plant equipment in their books.

It is the sum of following:

- Present cost of purchasing same or similar assets (plant equipment). The emphasis here is on present cost and not the cost of equipment at the time of its original purchase 10 years ago!

- Present cost of installation and commissioning.

- Any associated cost of carrying out the replacement project. For example, cost of removal and disposal of existing plant equipment and cost of imparting fresh trainings to maintenance manpower for any technology differences in the new plant.

Sounds complicated, right? – It is!

How do you determine the Replacement Asset Value (RAV)?

While it would seem natural to go out in the market and obtain fresh quotes from manufacturers for present value of the plant equipment and the cost for its installation and commissioning, it is not the method of choice in industry for ascertaining the Replacement Asset Value (RAV). Why? – because it is not simple.

Even simple industrial plants and facilities have a multitude of components and equipment belonging to different manufacturers. Reaching out to each of them and obtaining quotes is not as simple as it may sound. So, what’s the solution?

The preferred method of estimating RAV owing to its simplicity is based on initial plant costs. It is to simply check what was the cost of procurement, installation and commissioning of the plant (say) 20 years ago when it was installed and adjusting for inflation.

Remember that Replacement Asset Value (RAV) is an estimate and is treated as such. Otherwise, the actual cost of replacing the plant equipment will only be revealed when a new project is practically undertaken.

So, for example, if a thermal power plant was installed in (say) 2003 for USD 100 million, its RAV in the year 2023 will account for inflation adjustment for a period of 20 years. The inflation adjustment would try to answer the question that what do USD 100 million in 2003 equal in today’s dollar value. It will always be much greater than USD 100 million.

Using the Metric – The Struggle of Finding References for Benchmarking

Let’s say you work out the RAV to Craft-wage employee headcount for the thermal power plant you are working in as a maintenance manager.

You find that the RAV of your plant is (say) USD 100 million and there are a total 65 number of maintenance labor categorized as craft-wage. Resultantly, your RAV to Craft-wage employee headcount is USD 1.53 million.

Now what? – Is this value good? Is this value bad? How to interpret it?

This is where you may feel corrected. You might have thought that just by calculating the metric, you’d be good to go, right?

Not so fast!

The value of the metric when looked individually does not convey any meaning. Its interpretation can only be done by comparing it with a benchmark or reference value.

The last step is to find references for benchmarking. This is the part that is sometimes frustrating.

You Cannot Find Universal Reference Values of the Metric for Comparison

You have to realize that there cannot be a universal reference value for RAV to Craft-wage employees headcount. Why? – because it cannot be.

This metric is dependent on nature of your industry. For example, if you are in a thermal power plant, you will definitely have a lot of manpower of mechanical trade because there is a lot of work of mechanical nature in thermal power plants including overhauling of boilers and turbines that are very labor-intensive maintenance activities.

On the hand, consider the example of an electrical grid station. Its maintenance is not mechanical in nature like a power plant because electrical equipment doesn’t need that much of overhauling and intrusive maintenances.

The RAV to Craft-wage employee headcount ratio of a power plant can never be compared with an electrical grid station because the former is by nature is a much more labor-intensive industry than the latter.

What’s the Solution?

If you are a power plant maintenance manager, liaison with other similar power plants to get a reference value.

If you are an electrical grid station maintenance manager, liaison with other similar grid stations to get a reference value.

Maybe shoot an email to a connection in a coveted organization that deals in the same industry as yours and request him to share the metric with you.

In short, you will have to reach outside of your own circle to get reference values for comparison. Once you have them, you can understand whether your own metric value is good or bad.

Final Word

The process of evaluating the RAV to Craft-wage Employee Headcount metric and finding reference values for benchmarking may require some hard work. However, once it is done, you get a very clear perspective of where you are standing in terms of maintenance management and efficiency of maintenance labor.

References & Further Reading

We would suggest that you review the following resources for further understanding the concepts presented in this article:

Other Articles You May Like

brizy_dc_post_title

Learn about Autonomous Maintenance - part of Total Productive Maintenance that empowers machine operators in basic maintenance tasks.

brizy_dc_post_title

Learn what is RAMS - acronym of Reliability, Availability, Maintainability & Safety/Supportability - in industrial maintenance.

brizy_dc_post_title

We explain what is the supposed role of Maintenance Planning Department in industry. We clear misconceptions and give do's and don'ts.

brizy_dc_post_title

Explaining 6 industrial maintenance types: Preventive, Reactive, Corrective, Predictive, Proactive and Reliability Centered Maintenance.

brizy_dc_post_title

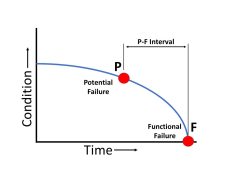

Practical aspects of PF Curve and PF Interval in maintenance & reliability explained. Learn what's the most important question in PF interval?

brizy_dc_post_title

The practical application of ABC classification of inventory for maintenance spare parts with examples from different industries.

brizy_dc_post_title

We explain the concept of Inherent Reliability - A metric used in industrial maintenance and reliability management.

brizy_dc_post_title

Intuitive explanation of Achieved Availability - Metric used in Industrial Maintenance & Reliability Management.

brizy_dc_post_title

Explaining in simple English the term Mean Time To Repair or Replace (MTTR) used in maintenance management.

brizy_dc_post_title

We explain the terms Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) in simple and practical language.

brizy_dc_post_title

We give a detailed example of calculating Overall Equipment Effectiveness (OEE) for HVAC equipment (in a story telling style).

brizy_dc_post_title

Explaining the 8 wastes of lean manufacturing (or lean production) philosophy that are applicable on maintenance management.

brizy_dc_post_title

Intuitive explanation of the difference between Total Effective Equipment Performance (TEEP) & Overall Equipment Effectiveness (OEE).

brizy_dc_post_title

We explain in layman terms what is Overall Equipment Effectiveness (OEE) - a metric maintenance teams aim to maximize in industry.

brizy_dc_post_title

We explain a useful metric that is used by maintenance managers to determine efficiency of their maintenance workforce.

brizy_dc_post_title

We explain the maintenance work order system (or work management system) used by maintenance departments in simple words.