Torque Wrench Calibration | Why, When & How - Complete Guide

Torque wrench calibration is an important topic to discuss because torque wrenches are an essential tool for anyone involved in mechanical work dealing with bolts and screws. Whether you are a workshop owner or a DIYer, torque wrenches are used for a wide variety of applications from dismantling and assembling of engines and suspension components to tightening lug nuts of your car.

In the industry, torque wrenches have applications much greater in scope and variety than automotive works as disassembly and re-assembly of heavy-duty machines requires tightening each fastener at the torque specified by the manufacturer. In order to ensure safety and integrity of mechanical equipment you are working with, it is necessary that you get your torque wrench calibrated periodically.

Why do you calibrate a torque wrench?

The answer of why a torque wrench needs to be calibrated lies inside the question of why a torque wrench is needed at all? Why not simply tighten bolts by the feel of how much force are we exerting using a conventional wrench? – That was how things were once until torque wrench was invented.

Let’s take the simple example of your car’s lug nuts. The purpose of lug nuts is to hold the wheels of your car together with the axle. If lug nuts are loose, there is risk that your car’s wheel will leave the axle while you are driving and cause a fatal accident like the ones shown below,

(Video Credit: “POWERNATION” YouTube Channel)

Just like loose lug nuts can cause accidents, overtightened lug nuts can also cause similar accidents because overtightening can compromise the outer threads of studs or the internal threads of lug nuts. In order to make sure that the lug nuts are neither loose nor overtightened, a torque wrench is used. When designing lug nuts, engineers work out the ideal torque at which the lug nuts will neither exert too much clamping force on the wheel-axle mechanism nor too less. This information is available in your automobile’s owner’s manual.

Torque wrench calibration is required because torque wrenches have the tendency to lose their accuracy over time as the internal mechanism of a torque wrench is mechanical in nature that requires adjustment after certain period of use. An uncalibrated torque wrench is not trustworthy because you never know the torque at which it is tightening the fastener and that completely kills the intended purpose of using a torque wrench which is to make sure no overtightening or under-tightening is taking place.

While you car’s lug nuts are easily accessible and can be frequently checked, there are many critical fasteners that are difficult to access for example the engine cylinder head bolts and connecting rod bolts that will only get checked during engine overhauling and that is not something that happens frequently. In fact, if you take good care of your car, you might not need engine overhauling for 10-20 years. Therefore, it is imperative that such bolts are tightened with the right amount of torque the first time as well as whenever an engine is disassembled as illustrated in the video below.

(Video Credit: “POWERNATION” YouTube Channel)

Torque Wrench Calibration Standard

ISO 6789-2 (Requirements for calibration and determination of measurement uncertainty in hand torque tools) defines the requirements for calibration of torque wrenches as well as other torque measuring tools. As per the standard, torque wrenches must carry a "Traceable Calibration Certificate" that refers to a piece of document bearing information of torque wrench calibration details including the facility from where it was calibrated, the date of calibration and range of error.

How often should a torque wrench be calibrated?

As per the standard, following factors determine the interval of calibration of torque wrenches,

1. The required maximum permissible error based on the type of application you are using the torque wrench for. For example, an error of +/-4% is acceptable in majority of applications, however, for research projects in precision engineering, you may need a torque wrench with +/-2% error otherwise it may affect the results of your research.

2. Frequency of use is another factor that determines how frequently you need to calibrate your torque wrench. For example, if your torque wrench is being used in a automobile workshop tightening a hundred fasteners each day, it is likely that it will lose its accuracy earlier than a torque wrench used for occasional DIY applications.

3. Typical load during torque wrench operation is another factor determining the frequency of calibration. A general rule of thumb often followed by technicians and workshops is not to use the torque wrench for more than 80% of its maximum torque value i.e. if the maximum torque limit on your torque wrench is 100 N.m, it is advisable not to use it for torqueing bolts and screws requiring a torque of more than 80 N.m. If you are using the torque wrench more often near its peak value, it may require calibration earlier than if you were using it in say 50% of its range.

4. Ambient conditions during operation can also have an effect on torque wrench calibration frequency. That is so because of the effect of temperature on metallurgy of materials making up components of the torque wrench. Since metals expand in heat and contract at lower temperatures, it affects the accuracy of torque wrench in different seasons, however, for most practical applications, the loss of accurcy is likely to be negligible. Such a problem is more noticeable for precision engineering applications.

5. Storage conditions can also affect the accuracy of torque wrenches. For example, it is advisable to dial down your micrometer click type torque wrench to its minimum value in storage as it relieves spring tension and preserves accuracy.

There can be other factors specific to different applications that could determine how often your torque wrench may require calibration.

ISO 6789-2 refers to a "Control Procedure" that, in simple terms, refers to documenting record of your torque wrench to track its use. It can be in the form of a logbook that records the daily usage of torque wrenches as well as recording any misuse, mishandling or accident with the torque wrench. Such a documented record will enable you or your workshop to remain confident of the accuracy of the torque wrench and ascertain the frequency of calibration best suited to your applications.

However, in case such a "Control Procedure" is not in effect, that is generally the case with majority of the torque wrenches used in workshops and DIY, ISO 6789-2 recommends calibration every 12 months or 5,000 cycles, whichever occurs first. In the light of this point, you should get your torque wrench calibrated at least once a year.

Alternatively, you may record the number of times you use your torque wrench in a day or a week (or any period of choice) and extrapolate it to estimate the number of weeks or months in which your torque wrenches reaches 5,000 cycles. It will give you a good idea of whether you need to get your torque wrench calibrate more than once a year or not.

The above factors determine periodic calibration frequency of torque wrenches, however, there can be certain occurrences that necessitate calibration separately from the periodic calibration. Such factors include,

1. Overload: If you have subjected your torque wrench to an overload, it will require calibration. For example, you have a torque wrench with maximum range of 100 N.m. You mistakenly kept apllying pressure on the torque wrench even after it clicked at 100 N.m. Under such an occurrence, it is necessary that you get your torque wrench calibrated again. ISO 6789-2 specifies that calibration is required if an overload of 125% is applied i.e. while the maximum value of torque wrench is 100 N.m, you used it for 125 N.m.

2. Repair: If you have got your torque wrench repaired, it will need calibration immediately. That is so because repair requires disassembly of torque wrench in most of the cases that disturbs the internal adjustments made in last calibration resulting in loss of accuracy.

3. Improper Handling: If your torque wrench has been improperly handled such as it fell from considerable height or got stuck somewhere experiencing abnormal forces, you need to get it calibrated.

Who can calibrate my torque wrench?

A Snap-On Digital Torque Checker displays the amount of torque being applied by a torque wrench.

Torque wrench is calibrated by accredited facilities dealing with calibration of measuring tools and equipment. The calibration facility will have a special piece of equipment that the ISO 6789-2 calls a measuring device.

It is a device that is used to calibrate a torque wrench. There are multiple types of calibration devices, however, we will explain with an example of a digital torque measuring device like the one manufactured by Snap-on that is a digital torque checker.

It simply consists of a display screen over which the torque applied over a hex or square drive is displayed. You take readings by applying torque over the drive by using the torque wrench that is to be calibrated as illustrated in the video below.

(Video Credit: "Rob Precision Tool Service" YouTube Channel)

It is important to highlight here that this measuring device itself needs calibration periodically as per ISO 6789-2 (section 4.3) according to which, the measuring device must hold a valid calibration certificate from a laboratory that meets the requirements of ISO 17025 (General requirements for the competence of testing and calibration laboratories). The same section also allows calibration of the measuring device from a facility that meets the national measurement standard.

The factors determining frequency of calibration of the measuring device (used for calibrating torque wrenches) are similar to the torque wrenches themselves and include the following as per ISO standard under discussion,

1. Overload

2. Repair

3. Improper use

In the absence of a "Control Procedure", it specifies a period of 24 months for its calibration.

Do all torque wrenches need to be calibrated?

Coming towards the discussion of torque wrench calibration for different types available in the market such as mechanical click type, dial type and electronic torque wrenches, it must be highlighted that all types of torque wrenches need calibration.

ISO 6789-1 on requirements and methods for design conformance testing and quality conformance testing - minimum requirements for declaration of conformance of torque tools divides torque wrenches as well as other torque measuring tools in 12 classes given hereunder,

Type-I Indicating torque tools with following classes,

Class A: Wrench, torsion or flexion bar

Class B: Wrench, rigid housing, with scale or dial or display

Class C: Wrench, rigid housing and electronic measurement

Class D: Screwdriver, with scale or dial or display

Class E: Screwdriver, with electronic measurement

Type -II Setting torque tools with following classes,

Class A: Wrench, adjustable, graduated or with display

Class B: Wrench, fixed adjustment

Class C: Wrench, adjustable, non-graduated

Class D: Screwdriver, adjustable, graduated or with display

Class E: Screwdriver, fixed adjustment

Class F: Screwdriver, adjustable, non-graduated

Class G: Wrench, flexion bar, adjustable, graduated

All of the torque wrenches available in the market will fall in either of these categories. For example, mechanical click type torque wrenches would fall under Type-I Class B; electronic or digital torque wrenches will fall under Type-I Class C and deflecting beam type torque wrenches will fall under Type-I Class A. The same standard goes on to give the maximum permissible error for each category with the term “maximum permissible relative deviation”. Wherever there is chance of loss of accuracy, there is need for calibration.

What is the accuracy of a torque wrench?

ISO 6789-1 gives maximum permissible deviation for different classes of torque wrenches in section 5.1.5. Class A & D in Type-I torque wrenches have permissible deviation of +/- 6%. Class B, C & E in Type-I torque wrenches has permissible deviation of +/- 6% for smaller torque wrenches in which the maximum torque limit is less than 10 N.m while it is more stringent at +/- 4% for torque wrenches having maximum limit above 10 N.m (that covers majority of the torque wrenches used in professional as well as DIY applications).

How do you calibrate a torque wrench?

The basic principle of calibration of any measuring tool is to compare its set value against a true value. For example, if you want to check whether or not your weighing scale is giving an accurate reading of weight, you can put a 05 lbs. weight over it and see if it reads 05 lbs. or not. If it gives 5.5 lbs. you will not remain confident of your weighing scale. Same is the case with torque wrenches but just a little more sophisticated.

The exact procedure for calibration of a torque wrench is available in ISO 6789 standard. The procedure is explained in simple terms as under,

1. Setting the torque wrench to 20% of its torque range. Use torque measuring device to record the torque value at which your torque wrench clicks.

2. Finding the error percentage. For example, if you had set 20 N.m at the measuring device showed 24 N.m, it means there is an error of 4 N.m i.e. 20%.

3. Repeat steps 1 and 2 at 60% and 100% of torque values.

4. Open up the locking nut of your click type torque wrench and adjust the spring tension mechanism as per directions of the manufacturer.

5. Close the torque wrench and repeat steps 1 to 3 again to check if the error has dropped to specified range.

6. If error has been reduced within acceptable range (+/-4% for mechanical click type torque wrenches above 10 N.m limit and +/-6% for below 10 N.m limit i.e. smaller torque wrenches) than you have been successful. If the error is still out of acceptable limits, repeat above steps in an iterative manner until error is reduced to fall within acceptable range.

While there are some DIY techniques you can use for calibrating your torque wrench at home, however, it is not advisable to do it yourself with regular tools and equipment at home or workshop because the accuracy of such techniques cannot be guaranteed.

Should you double click a torque wrench?

There is debate on this issue where some people would say it is okay to do so while other would advise strongly against it, however, we don’t seem to think there is any problem in double clicking your torque wrench to make sure you have tightened a critical fastener at the required torque.

However, do remember our discussion on calibration frequency above where we explained that you should calibrate your torque wrench once a year or after 5,000 cycles, whichever occurs first because each time you click, you should count it in those 5,000 cycles. Therefore, you should not make a habit of double clicking your torque wrench as it would require you to get it calibrated earlier than you might expect.

How should a torque wrench be left after use?

It is recommended that a mechanical click type torque wrench may be dialed down to its minimum value after use to preserve its accuracy. It is so to relieve the tension of its spring mechanism that is responsible for making it click at the right torque.

How do you check a torque wrench without any measuring device?

If you want to check the accuracy of your torque wrench yourself, you can compare it with another torque wrench whose value you trust. Simply tighten a bolt at an arbitrary torque, say 50 N.m with your torque wrench. Set the trusted torque wrench to 50 N.m and tighten the same bolt. If the bolt head moves before the trusted torque wrench clicks, it means your torque wrench is under-torqueing.

If it clicks without turning the bolt, it would mean that either your torque wrench is okay or it has overtightened the bolt. To make sure of it, you need to take one more step. Set the torque on trusted torque wrench a little higher and apply torque on the same bolt. If it turns now (while it hadn’t turned before), it means your torque wrench is accurate because it clicks the same as a trusted torque wrench.

This is just a DIY way of testing your torque wrench and by no means be considered an alternative of calibration.

Torque Wrench Calibration Certificate

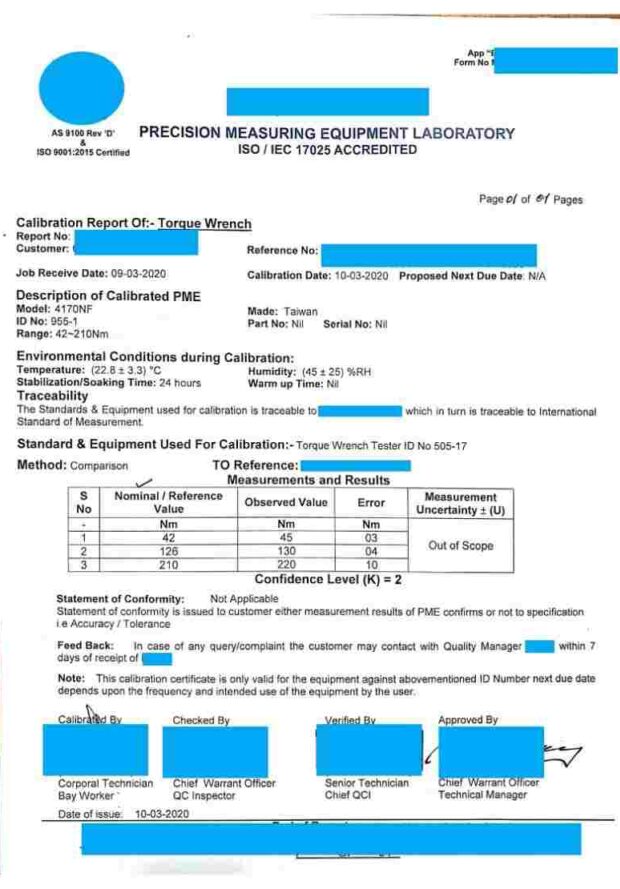

Torque wrench calibration certificate is issued by the calibration lab or facility against the specific torque wrench they calibrated. The certificate contains important information including the date of calibration; values at which calibrated and amount of error observed during calibration. There can be different forms of calibration certificate, however, all certificates will provide the afore mentioned information.

Sample of a torque wrench calibration certificate issued by ISO certified calibration lab

How much does it cost to calibrate a torque wrench?

The cost of calibration depends on the following factors,

1. Torque range of your torque wrench. The greater the range, the higher the cost.

2. Type of torque wrench for example electronic or mechanical.

3. Facility Reputation from where you are getting your torque wrench calibrated. Well reputed facilities that have accreditation of relevant ISO standards will definitely charge more but their calibration certificate will be more trustworthy.

4. Sometimes, charges for different brands of torque wrenches are different because of the complexity involved in making adjustments in their mechanisms to restore accuracy.

Based on above factors, the cost can be from $20-$40 to a few hundred dollars. That being said, majority of the torque wrenches used in automobile workshops and DIY applications will get calibrated at around $40-$50.

Check the resources below to get more idea of torque wrench calibration charges,

MountzTorque Charges for Torque Wrench Calibration

Custom Calibration Solutions LLC Charges for Torque Wrench Calibration

Tohnichi America Charger for Torque Wrench Calibration Services

There are many good quality torque wrenches that come with a calibration certificate. You can check our post on our torque wrench recommendations.

If you like our post and the information we have presented, please do give your valuable feedback and share this article with your friends.