WEN 6550 vs 6552 Benchtop Thickness Planer

Updated: 17-September-2023

Electric thickness planers have made life easier for woodworkers and DIYers by automating a job that was otherwise strenuous when done with the help of hand planer. Benchtop thickness planers get the job done effortlessly and in much less time.

Our today's post is based on comparing WEN 6550 vs 6552 - two benchtop thickness planers that are both great value for money. We have compared the two models in different areas of performance and reliability. So without further due, let's begin.

Overview of Main Specifications

Parameter | WEN 6550  | WEN 6552  |

Max. width of board | 12.5" | 13" |

Max. thickness of board | 6" | 6" |

Weight of unit | 77 lbs. | 67 lbs. |

Feed Rate | 26 ft./min. | 26 ft./min. |

No. of cutting blades | 02 | 03 |

Max. current drawn from source | 15 Ampere | 15 Ampere |

Cuts per minute | 17,000 | 25,500 |

Comparison in Cutting Capacities

We begin the comparison with cutting capacities that include the maximum size of stock these planers can work with. WEN 6552 wins in this area as it has slightly greater capacity. It can work with 13” wide boards with a maximum thickness of 6”. While thickness capacity of WEN 6550 is same, its maximum working width is 12.5”.

The feed rate on both WEN 6550 and 6552 is same i.e. 26 feet per minute that means none of the them have any advantage over the other in terms of how much lumber can you process through them in a single workday.

The maximum cutting depth for a single pass is also same for both models i.e. 3/32”.

Let’s give 1 point to WEN 6552 for having an 0.5” advantage over WEN 6550 in maximum width of board it can work with.

Planer | Points Gained | Cumulative Points |

WEN 6550 | 0 | 00 |

WEN 6552 | +1 | 01 |

Stability Comparison

Since planers are used for working with long stocks including constructional lumber, the weight of the stock can make the planer vibrate or wobble during use. It is therefore important for a planer to remain stable and firm during use.

The weight of the WEN6550 planer (77 lbs.), partly attributable to its cast iron base adds stability to the planer so that it does not vibrate or wobble during operation. In case you are not satisfied with its stability, the planer features mounting holes in its base that can be used to bolt the planer down to a stable base.

The design of WEN 6552 is similar to 6550, however, it weighs 67 lbs. i.e. it is 10 lbs. lighter than WEN 6550. Lighter weight adds to portability (which we will discuss later), however, loses some points on stability.

Planer | Points Gained | Cumulative Points |

WEN 6550 | +1 | 01 |

WEN 6552 | 0 | 01 |

Maintenance Aspects Comparison

A benchtop planer will require maintenance over time to keep the planer in a good condition. It is important for a tool to have good maintainability i.e. it is not difficult to carry out maintenance tasks on the tool. In this regard, we have compared the two planers on maintenance related aspects.

Disassembly & Adjustment of Dust Extraction Port

On both models, the dust extraction port is easily removable with the help of thumb screws i.e. you don’t need any screwdriver or wrench to remove it. It is tool free. It allows convenient servicing, cleaning and change of orientation.

Dust extraction port on both models are easily disassembled without any tool.

Similarly, the dust extraction port on both models can be installed in both directions that is a nifty feature to allow you to align the port with your shop vacuum system instead of rotating the whole planer.

Planer | Points Gained | Cumulative Points |

WEN 6550 | +1 | 02 |

WEN 6552 | +1 | 02 |

Ease of Blade Replacement

Blade replacement on WEN6550 is quite convenient. You will need only one tool, a wrench that comes with the planer, to remove the blades. After removing the vacuum port with thumb screws, you get access to two screws to remove blade guard with the help of the given wrench. The same wrench then removes the 6 blade gib screws to free the blade.

Standardization of screw sizes to allow a single wrench to disassemble the unit is a notable feature. Convenience in blade replacement doesn’t end here. There are two magnets stored onboard on the planer that are used to remove the blade from its housing after it has been freed from its screws.

Moreover, the blade guard you had removed earlier has a built-in tray to store the removed screws and your wrench to avoid misplacement. WEN6552 has almost the same procedure and benefits. Both units are equally good in this area. The blades on both planers are also reversible so that you may reverse them for avoiding uneven wearing out.

Planer | Points Gained | Cumulative Points |

WEN 6550 | +1 | 03 |

WEN 6552 | +1 | 03 |

Magnets & Hex Key required for removing blades is stored on-board

Cleaning & Servicing After Use

The granite infeed and outfeed tables of 6550 are smooth and require minimal effort to remove sawdust after use. Moreover, granite is non-marring to ensure the smoothness that stands out is not a temporary out of the box advantage. WEN6552 does not enjoy the same advantage as it does not feature granite tables.

Motor and cutter bearings on both the planers are sealed with no need for lubrication. However, gears do require greasing on both models.

Planer | Points Gained | Cumulative Points |

WEN 6550 | +1 | 04 |

WEN 6552 | 0 | 03 |

The granite surface on WEN 6550 has anti-stick surface that is easy to clean

Ease of Replacing Motor Brushes

Both planers have motor brush caps that are easily accessible. You just have to remove the cap and remove spring loaded brush, replace it and put the cap back on. It makes maintenance simple and convenient.

Planer | Points Gained | Cumulative Points |

WEN 6550 | +1 | 05 |

WEN 6552 | +1 | 04 |

Motor brushes on both WEN 6550 & 6552 are easily accessible

Comparison in Portability

Two main features stand out with respect to portability of WEN6550 as well as WEN6552. One is the foldable infeed and outfeed tables to make the overall unit more compact. The other is the set of handles used for conveniently gripping and holding the planer to move it from one point to another.

Both models have handles for conveniently gripping the unit and carrying from one point to another

However, what gives WEN6552 an edge over WEN6550 in the area of portability is its comparatively lighter weight. WEN 6552 weighs at around 67 lbs. whereas WEN 6550 weighs around 77 lbs. The 10 lbs. difference in weight makes 6552 easier to carry than 6550.

Planer | Points Gained | Cumulative Points |

WEN 6550 | 0 | 05 |

WEN 6552 | +1 | 05 |

Ergonomics Comparison

Ergonomics refer to the tool being made fit for the user such that the user feels comfortable in using the tool. It is an important aspect of comparison because once purchased, you would be using your planer for many years to come. So let's compare the two models on some ergonomics related aspects that stand out for these machines.

Noise

WEN6552 is quite loud and would require you to wear head gear. The noise is most noticeable in close environments such as a garage or a workshop. WEN6550 on the other hand is quieter in comparison thereby offering greater comfortability with the use of the tool especially for long durations.

Planer | Points Gained | Cumulative Points |

WEN 6550 | +1 | 06 |

WEN 6552 | 0 | 05 |

Stock Return

You have to pass stock multiple times through the planer to achieve the desired thickness and finish. A convenient way of returning the stock at the infeed table of the planer for a second pass is to pass and push it over from the top of the planer itself.

One handy advantage WEN6552 has over WEN6550 is the availability of two rollers at the top of the planer that allow easier rolling of stock on top surface of the planer.

Planer | Points Gained | Cumulative Points |

WEN 6550 | 0 | 06 |

WEN 6552 | +1 | 06 |

Stock return rollers on WEN 6552 help you to conveniently return the lumber for second pass

Depth of Cut Gauge

Another area where WEN6552 has an advantage over 6550 is depth of cut gauge located at the infeed of the planer. It allows you to easily check the depth of your stock in each pass through the planer so that you may make precise adjustments in the cutting depth of the planer for the next pass. WEN6550 does not feature any depth gauge.

Planer | Points Gained | Cumulative Points |

WEN 6550 | 0 | 06 |

WEN 6552 | +1 | 07 |

Depth of cut gauge on WEN 6552 gives a clear visual indication of how much more thickness needs to be shaved off in the next pass

Comparison in Design of Table

Design of table in electric planers is an important aspect as the stock has to slide over the table all by itself as it passes through the planer. The most desirable merit of infeed, outfeed and central table is sustainable smoothness. The table must be able to allow stock to pass through the planer with no resistance offered by the table due to friction.

Friction not only causes the planer motor to work harder but may also leave marks on the stock. Moreover, this smoothness must be able to last for long. It shouldn’t be that the buttery smooth finish of the table out of the box diminishes over usage.

The granite table on WEN6550 is heavy and smooth. It not only provides a very stable base for the flow of stock but also keeps the flow buttery smooth through the planer. Granite does not loose its smoothness over time.

On the other hand, WEN6552 does not feature granite table therefore does not offer the same advantages as mentioned for WEN6550. However, WEN6552 has a reflective central table that reflects the image of cutting blades concealed from the user.

It is important to clarify that the granite table on WEN6550 is only the central part i.e. infeed and outfeed tables are not made of granite. Moreover, the central part of table is not entirely made of granite but consists a layer of granite on its surface. Nonetheless, the difference in smoothness of flow and overall feel is not to be underestimated. Granite table is a key feature of WEN6550 that gives it a major advantage over WEN6552.

Planer | Points Gained | Cumulative Points |

WEN 6550 | +1 | 07 |

WEN 6552 | 0 | 07 |

The granite central table on WEN 6550 is non-marring and scratch free. Its smoothness allows frictionless flow of stock through the planer.

Comparison in Safety & Longevity Features

As said earlier that you would be using the planer you purchase for years to come, another important aspect of comparison is the set of safety features and longevity features included in the two models. Safety here refers to human safety from potential dangers of the tool and longevity refers to inclusion of such features that improve tool's life. So let us compare the two models on these aspects.

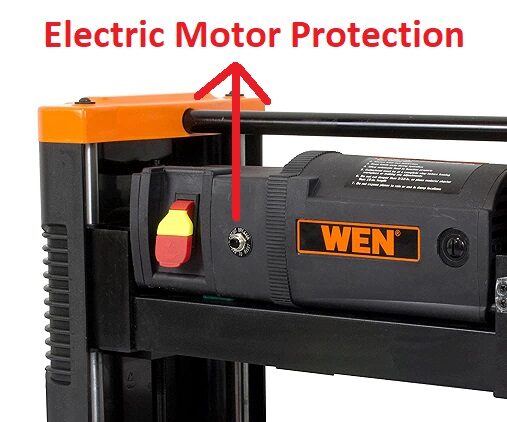

Electrical Protection for Motor

Both planers feature electrical protection with the help of a circuit breaker than trips power to the motor when motor when motor gets overloaded or heats up. It prevents permanent damage to the tool. However, you have to take care yourself that planer is not turned on when you reset the circuit breaker. It would’ve been better if the planers had a safety for unintentional tool startups.

Planer | Points Gained | Cumulative Points |

WEN 6550 | +1 | 08 |

WEN 6552 | +1 | 08 |

Both planers feature electric motor protection circuit breaker to save motor from burnout

Child Safety Lock

Both planers feature a child safety lock. It comes in the form of a small key to be removed the main ON/OFF switch. As long as the key is removed, the planers will not turn on. They will turn on only when the key is inserted back. You can remove the key after closing of work so that the tool is not able to start in your absence.

Planer | Points Gained | Cumulative Points |

WEN 6550 | +1 | 09 |

WEN 6552 | +1 | 09 |

Child safety lock is available in the form of a key to be inserted in main on/off switch. It prevents unintentional tool startups

Durability

While body of both planers is solid and durable, the gears are not metallic. Both planers have plastic gears that are not as durable as metal gears.

Planer | Points Gained | Cumulative Points |

WEN 6550 | 0 | 09 |

WEN 6552 | 0 | 09 |

Comparison in Quality of Job

The end result of a good thickness planer is a smooth finish with desired thickness throughout the length of the stock.

WEN 6550 has two cutting blades with a cutting speed of 17,000 cuts per minute. WEN 6552 features three cutting blades with a cutting speed of 25,500 cuts per minute. Although WEN 6552 has better specifications on paper in this area, the surface finish quality of both planers is satisfactory. Both planers produce above 180-ish grit surface finish.

However, snipe is an issue with WEN6550 planer. It planes the entry part of the board by a greater cutting depth than rest of the board. It can be resolved by introducing a sacrificial length of board to be cut off later. Although snipe is removed by adjusting the infeed and outfeed tables on most planers, with WEN 6550, the problem remains to some extent even after adjustment.

The same problem is not experienced in WEN 6552.

Planer | Points Gained | Cumulative Points |

WEN 6550 | 0 | 09 |

WEN 6552 | +1 | 10 |

Verdict

With a 02-Year warranty offered by WEN, both models are close competitors to each other. However, we have found WEN 6552 benchtop thickness planer to have an edge over WEN 6550 as presented by the final points,

Planer | Points |

WEN 6550 | 09

|

WEN 6552 | 10 Winner |

At the time of this review, WEN 6550 is priced around $300 and WEN 6552 around $360.

We found WEN 6552 to have advantage over WEN 6550 in the areas of cutting quality, ergonomics, portability and slight edge in maximum width of board that can be worked with. Based on these merits, our recommendation for our readers is WEN 6552 benchtop thickness planer.