Total Effective Equipment Performance (TEEP) vs. Overall Equipment Effectiveness (OEE)

The Difference Decoded

In our earlier article, we explained in layman terms what Overall Equipment Effectiveness (OEE) means. The Total Effective Equipment Performance (TEEP) is also a similar metric but is a different metric than Overall Equipment Effectiveness (OEE).

While the difference between the formulas of Overall Equipment Effectiveness (OEE) and Total Effective Equipment Performance (TEEP) is quite clear, how the change in formulas impacts the meaning they deliver is not so clear.

This article is based on explaining the difference between the two metrics in an intuitive and simple way.

If you want to develop a deeper understanding of the difference between the Total Effective Equipment Performance (TEEP) and Overall Equipment Effectiveness (OEE), we highly recommend you understand Overall Equipment Efficiency (OEE) first from our previous article.

Let us see what Total Effective Equipment Performance (TEEP) is made of:

Total Effective Equipment Performance (TEEP) = Utilization x Availability x Performance x Quality Rate

Where all of the variables are expressed in percentages between 1-100%. If you observe closely, you will find that only one extra variable “utilization” has been added in Total Effective Equipment Performance (TEEP) as compared to Overall Equipment Effectiveness (OEE) such that:

Total Effective Equipment Performance (TEEP) = Utilization x OEE

Short Review of Overall Equipment Effectiveness (OEE)

We had already discussed in our article on OEE how it captures the “effectiveness” of plant equipment for the company. Let us present its short overview here again.

Overall Equipment Effectiveness (OEE) is a product of three variables:

- Availability

- Performance

- Quality Rate

Availability expresses what percentage of the time the equipment remained up vs. the time it was supposed to remain up. The lower the downtime of the equipment (due to any faults or breakdowns), the higher the availability percentage.

If an automated packaging machine remained up for 90 out of the 100 hours it was supposed to remain up (and wrap plastic sheets around packages), its availability will be 90%.

Performance expresses what percentage of the time the machine performed at its rated performance parameters. So, for example, if the automated packaging machine had a rated speed of wrapping 100 boxes per hour but it actually wrapped with an average of 90 boxes per hour, its performance will be 90%.

Quality rate expresses what percentage of total products produced by a machine were defect-free. So, for example, if the packaging machine wrapped 90 out of 100 packages perfectly but 10 wraps were improper, its quality rate will be 90%.

What’s important to understand is that neither of the availability, performance and quality rate alone capture an important metric that the company wants.

If availability is 100%, it means that the packaging machine never broke down. However, is it enough?

What if it kept running slow due to some problem? Hence came performance. It is not enough for the machine to remain up (high availability), it is important that it runs at the rated speed (high performance) so that the packaging machine meets the target of quantity of products wrapped by the end of the shift.

However, is it any good if the machine produces lots of defective wraps? Would high uptime (availability) and high speed (performance) be of any use if the machine keeps producing defective wraps?

Of course, no. Hence came quality rate.

So, Overall Equipment Effectiveness (OEE) combined all three metrics with each other to superimpose their importance over each other. OEE will be high if and only if all three metric i.e., availability, performance and quality rate are high.

Only when the availability, performance and quality rate of the machine are simultaneously maintained high will you get a high value for Overall Equipment Effectiveness (OEE).

The One Metric That Creates the Difference Between TEEP & OEE

A high value of Overall Equipment Effectiveness (OEE) will make the factory owner happy because it will convey that he is extracting maximum value out of his machines. Or is he?

Maybe something is missing?

What could be missing?

We’ve seen how Overall Equipment Efficiency (OEE) has already captured high uptime (availability), high speed (performance) and defect-free products (quality rate). What else could possibly be left behind?

The very reason why Total Effective Equipment Performance (TEEP) exists is because Overall Equipment Effectives (OEE) still misses one thing.

That one thing is what we referred at the start of the article i.e., “utilization”.

If you understand what “utilization” means and how it complements Overall Equipment Effectiveness (OEE), you’ll get the crux of what Total Effective Equipment Performance (TEEP) is all about.

Remember we started the story of Overall Equipment Effectiveness (OEE) from its first variable i.e., “availability” which is the percentage uptime of a machine. If the packaging machine we’ve been giving example of remains up in the 8 hour work day from 9am to 5pm without any breakdown or faults, its availability will be 100%.

Let’s say that in those 8 hours, the machine never slowed down (100% performance) and the machine never produced even a single defect (100% quality rate) then its Overall Equipment Effectiveness will be a perfect 100%.

“Utilization” is the metric that takes one step back from the above story. It asks if the packaging machine is designed by the manufacturer to run just 8 hours a day? Is it inherently able to run more?

Let’s say it has been designed by the manufacturer to run 12 hours a day and it is the conventional factory hours routine that requires 8 hours of uptime from it from 9am to 5pm in a day.

In above case, the availability of the packaging machine will be a perfect 100%, its performance will be a perfect 100% and its quality rate will be a perfect 100%. These factors combined will make its Overall Equipment Effectiveness (OEE) will be a perfect 100%.

However, guess what will not be a perfect 100%?

Its utilization.

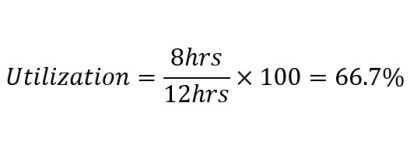

Its utilization will be:

Utilization expresses what percentage of the time did the machine was scheduled to do work or assigned work vs. the time it is designed to do work.

Therefore, if the packaging machine was designed by the manufacturer to be able to run 12 hours a day but it is scheduled to run only 9am to 5pm everyday, it means the factory is utilizing its machine only 66.7% of its capacity.

So, “Utilization” is the metric that expresses whether the factory is extracting every last ounce of work from its machine or not. If the factory owner has paid $500,000 for a packaging machine, why run it for 8 hours a day when it can run for 12 hours a day?

If an 8-hour work was needed, why not buy the other simpler variant that costs less?

Total Effective Equipment Performance (TEEP) in above example will not be 100% because utilization will bring the percentage down. So, while Overall Equipment Effectiveness (OEE) was a perfect 100%, Total Effective Equipment Performance (TEEP) will be 66.7% as calculated below,

100% availability x 100% performance x 100% quality rate = 100% OEE

but

66.7% utilization x 100% availability x 100% performance x 100% quality rate = 66.7% TEEP

Can you see how smartly Total Effective Equipment Performance (TEEP) has captured unutilized potential of plant equipment which Overall Equipment Effectiveness (OEE) failed to do so?

This is the main difference between Overall Equipment Effectiveness (OEE) and Total Effective Equipment Performance (TEEP).

While OEE tells the factory management whether or not the maintenance team is able to keep the equipment running in top notch condition throughout the time the machine is scheduled to run, TEEP tells whether that “scheduled to run” time duration has utilized the potential of machine i.e., “able to run”.

TEEP will be 100% only when the machine is run at its maximum capacity without any downtime, speed losses and quality issues.

We hope this explanation has made the difference between Total Effective Equipment Performance (TEEP) and Overall Equipment Effectiveness (OEE) very clear and simple. Please don’t forget to share our article with someone in need of it.

Other Articles You May Like

brizy_dc_post_title

Learn about Autonomous Maintenance - part of Total Productive Maintenance that empowers machine operators in basic maintenance tasks.

brizy_dc_post_title

Learn what is RAMS - acronym of Reliability, Availability, Maintainability & Safety/Supportability - in industrial maintenance.

brizy_dc_post_title

We explain what is the supposed role of Maintenance Planning Department in industry. We clear misconceptions and give do's and don'ts.

brizy_dc_post_title

Explaining 6 industrial maintenance types: Preventive, Reactive, Corrective, Predictive, Proactive and Reliability Centered Maintenance.

brizy_dc_post_title

Practical aspects of PF Curve and PF Interval in maintenance & reliability explained. Learn what's the most important question in PF interval?

brizy_dc_post_title

The practical application of ABC classification of inventory for maintenance spare parts with examples from different industries.

brizy_dc_post_title

We explain the concept of Inherent Reliability - A metric used in industrial maintenance and reliability management.

brizy_dc_post_title

Intuitive explanation of Achieved Availability - Metric used in Industrial Maintenance & Reliability Management.

brizy_dc_post_title

Explaining in simple English the term Mean Time To Repair or Replace (MTTR) used in maintenance management.

brizy_dc_post_title

We explain the terms Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) in simple and practical language.

brizy_dc_post_title

We give a detailed example of calculating Overall Equipment Effectiveness (OEE) for HVAC equipment (in a story telling style).

brizy_dc_post_title

Explaining the 8 wastes of lean manufacturing (or lean production) philosophy that are applicable on maintenance management.

brizy_dc_post_title

Intuitive explanation of the difference between Total Effective Equipment Performance (TEEP) & Overall Equipment Effectiveness (OEE).

brizy_dc_post_title

We explain in layman terms what is Overall Equipment Effectiveness (OEE) - a metric maintenance teams aim to maximize in industry.

brizy_dc_post_title

We explain a useful metric that is used by maintenance managers to determine efficiency of their maintenance workforce.

brizy_dc_post_title

We explain the maintenance work order system (or work management system) used by maintenance departments in simple words.