Complete Guide for Choosing a Brad Nailer

How do I choose a brad nailer?

Choice of the best brad nailer for your use depends on the details of your requirements. When you are about to invest 100-200 dollars in a tool, we would recommend noting down your requirements on paper before exploring different brands and models.

It is important to know what you need and then conduct market survey. Following main parameters come into play when choosing the best brad nailer for your application,

What type do you need? Pneumatic or Cordless?

If you already have an air compressor and don't feel any inconvenience in carrying a compressor and hose at job site, you don't need to switch to a cordless brad nailer because it carries added cost and is not as compact as pneumatic ones. However, cordless brad nailers will be a game changer if your application has portability at the top of priority list.

If you don't have a compressor and hose, add their cost to the price of pneumatic brad nailer before comparing it to a cordless brad nailer to make it a fair comparison.

Compactness & user fatigue component

Compactness will play a major role in your user experience with the tool especially if you are a professional who is using the tool all day long. A heavy tool will increase fatigue while a large tool might not easily fit in tight spots and narrow spaces such as working in small cabinets.

Don't compare pneumatic models with cordless ones because it is like comparing apples to oranges. Cordless models will always be heavier and larger than pneumatic ones because they house the motor and battery on tool while pneumatic models are hooked to an air compressor.

However, if you neither use the tool for extended periods of time nor you need to reach in tight spots, don't stress over compactness. For example, you don't need a compact tool for installing baseboards and quarter rounds, however, you do need a compact tool for making cabinets.

The most compact cordless model we found in our survey is Ryobi Cordless Brad Nailer Model P320 Airstrike while the most compact pneumatic model is Metabo HPT Brad Nailer Model NT50AE2.

Dry fire lock out should be available

It is quite probable that you wouldn't remember when your brad nailer is running out of nails and you would squeeze the trigger. This is where dry fire lockout feature comes into play.

An empty brad nailer will leave a mark on the workpiece when dry fired apart from harming its own pneumatic motor. To prevent that, a dry fire lockout is needed to prevent to tool from firing an empty air blow that might have oil stains in it.

However, dry fire lockout is not only for pneumatic brad nailers. Cordless brad nailers also need this feature because an empty fire can be harmful for the motor and will transmit sharp vibration to the workpiece that might leave an unwanted impression over it.

Nail length and magazine capacity as per requirement

When it comes to brad nailer, nail thickness is fixed to 18 gauge, however, there can be options in the length of nails it can work with and the maximum nails in can carry in its magazine before reloading is required.

Majority manufacturers give a nail length range of 5/8"-2" while some give up to 2-1/8" such as BOSTITCH Model BTFP12233 & BT1855K. Similarly, majority manufacturers give magazine capacity of 100 nails while some give up to 110 like Milwaukee 2740-20, DEWALT DCN680B & BOSTITCH BT1855K.

Generally, 2" nail length and 100 nails in the magazine are good enough for wide variety of applications, however, there can be unique scenarios where you need to drive 2-1/8" nails. Similarly, 10 additional nails per reload can save you a lot of time if you are bump nailing all day.

Depth of drive adjustment is a must

Depth of drive adjustment is available in almost all brad nailers from top brands but you should check it just in case. Depth of drive refers to the adjustment of how deep do you want the nail to go in the material.

You can set the depth of drive to highest for countersinking the nail in workpiece i.e. its head does not remain visible. You can set it to flush the nail i.e. keep its head parallel with the workpiece or you can set it at minimum if you want the head of the nail to stick out of the material for later finishing.

Do you need bump nailing?

Bump nailing refers to keeping the trigger squeezed and bumping the tool's nose tip on the job to fire nails. In technical terminology, it is called contact firing because once the trigger is squeezed, a nail is fired every time the tool tip makes contact with the job.

If you need to nail large lengths of wood without much consideration to distance between nails, bump nailing can get the job done very quickly. To check if the tool has bump nailing feature, simply find the term 'Contact Firing' in its flyer or literature.

No-mar nose tip is important

A no-mar nose tip is a very important feature. It basically refers to a rubberized soft tip that does not create any mark or impression over the surface of the workpiece when you press the tip on the surface. It is especially important when you are working with softer woods or crafts because they have a greater tendency to get affected.

Manufacturers generally state straight away when no-mar tip is included because it is such an important feature, however, if that information is not readily available you can check detailed literature of the tool or search customer reviews online to ascertain if no-mar tip is included or not. They are also available for purchase separately.

Maintenance aspects to be considered

The two main maintenance aspect with respect to brad nailers are its motor oiling and its jam release mechanism. Pneumatic brad nailers have to be oiled religiously, however, manufacturers are providing oil free pneumatic motors to eliminate this maintenance need. You must look for the term 'oil free' to get rid of maintenance. In case of cordless brad nailers, there is no oiling need.

Secondly, in case of a nail jam, brad nailer must have tool free jam release mechanism that makes it convenient to extract the stuck nail out of the gun.

Exhaust control/direction is important

With pneumatic nailers, you can run into a situation where the nailer's exhaust air hits the workpiece in such a way that all the dust is blown towards your eyes and face. Look for a nailer that has a muffled exhaust at the rear of the tool.

Or even better, look for a controllable exhaust port like a 360 deg. rotatable port provided by Metabo HPT Brad Nailer Model NT50AE2. It allows you to direct the exhaust air in whichever direction you want.

Small but lifesaving ergonomic features

There are some features that might not sound big but create a lot of difference during work such as,

1. LED light to illuminate the job in dark areas.

2. Window or slot for visual indication when tool is about to run out of nails.

3. Belt hook for convenient storage and carriage.

What's included in the package?

Always check what is included in the package. Cordless brad nailers might not have battery and chargers included. Similarly, no-mar tips might be sold separately. A carrying case is provided with most pneumatic models but not with cordless models. Metabo HPT Model NT50AE2 also includes safety glasses and hex bar wrenches while a few hundred nails are included in Ryobi P320 Airstrike and Craftsman CMCN618C1.

We are confident that if you will carefully note the factors explained above, you will make the right decision. We have also written a dedicated article on best brad nailers to get you jumpstarted with some good options.

Other Articles You May Like

brizy_dc_post_title

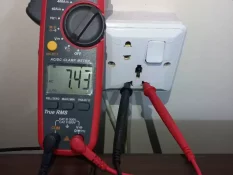

We explain how to test outlet with multimeter (or clamp meter) in 10 simple steps elaborated with pictures.

brizy_dc_post_title

We explain the difference between Milling and Welding - two manufacturing processes used for making stuff.

brizy_dc_post_title

Intro to welding skid with examples of custom made welding skids for pickup trucks & flatbeds. We also give important design considerations.

brizy_dc_post_title

We discuss the most important factors in selection of oscillating tool and answer some FAQs along the way.