A Guide to Choosing Oscillating Tool

How do I choose an oscillating tool?

An oscillating tool must be chosen such that it fulfills your requirements without being an overkill. You will have to list down the different types of jobs for which you need the tool and then check out different available models to match their pros with your priorities as well as cons with your acceptable compromises. Some important factors are as under,

Cutting Speed & Its Control

Oscillating tools come with different top speeds as well as different speed controls. If you are going to use the tool just for one job, for example, grout removal, you may not require many different speed settings. However, if you use your tool for a variety of different applications, it is better to go for a tool with lots of speed settings.

For example, Milwaukee 2626-20 has 12 speed settings from 11,000 oscillations per minute (OPM) to 18,000 OPM controlled through a variable speed dial. It allows the tool to be adjusted for a wide variety of applications. Slower speeds may be used on metal and faster speeds on wood.

If you look at Dewalt DCS356, it not only features 3 speed settings at 13000, 17000 and 20000 OPM through a variable speed dial but gives further control over through a double grip variable speed trigger that controls speed in each of the three speed settings proportionate to the pressure applied over the trigger.

On the other hand, Genesis GMT15A has a fixed speed setting with 21,000 OPM as its top speed.

Compatibility with tools and accessories of other brands

It is another important factor to consider. If you prefer buying from a single brand, it might not be so important for you to check compatibility, however, it is better to have a tool that accepts blades and accessories of other brands as well to increase flexibility in buying options.

For example, Genesis GMT15A has a universal fitment design that accepts blades from other brands without the need for any adapter or modification. On the other hand, Dewalt provides a universal accessory adapter for DWE315K, DCS356 and DCS354B that, once installed, makes the tool compatible with blades of other brands.

Example on the other extreme is the Fein FMM350QSL that has a special tool free and touch free blade fitment design named “Starlock” that doesn’t accept ordinary blades and accessories from other brands.

Maintenance & Tool Longevity Aspects

Some features are important to consider with respect to the maintainability and longevity of the oscillating tool especially if you are a frequent user. For example, a brushless motor is featured in many oscillating tools such as Dewalt DCS354B and DCS356 that improves tool efficiency and eliminates the need for replacement of motor brushes.

Another important feature in this regard is the electronic protection against overload and overheat to save the tool from permanent damage. In our research, Dewalt DCS354B and DCS356, Ryobi P340 and Makita XMT03Z have this feature in one form or another. Makita even gives a motor soft start feature to prolong motor life by reducing jerks during motor startup.

However, these features may be an overkill for you if you are an occasional user of the oscillating tool.

Ergonomics

Some important ergonomic factors to look for include,

1. Compactness of the tool in terms of the tool dimensions as well as weight. A compact tool will be easier to work with. For example, Galax Pro 22000 oscillating multi tool has a tool length of only 10.6”. Similarly Milwaukee 2426-20 has a tool length of merely 10.25” and weighs only 1.63 lbs. Compactness and light weight design reduces user fatigue.

2. Tool free accessory change is another great ergonomic and convenient feature present in Dewalt tools in our research. You wouldn’t need any wrench for changing blades on your tool. Fein FMM350QSL goes one step ahead with its touch free fitment system named “Starlock” that allows the blade to fall off and snap on to the tool without even touching it. It is particularly useful when you want to swap the blade after a cutting operation is performed and the blade is too hot to touch.

Warranty

Warranty is one of the most important consideration in buying any power tool because good warranty terms secure your investment in the tool. Top brands of oscillating tools are offering at least a 2-year warranty for their product. Milwaukee 2426-20 and 2626-20 have the longest warranty period in competition with 5-year long warranty. Dewalt comes at second with a 3-year warranty, 1-year free service and 90 days money back guarantee. Fein, Makita, Ryobi and Rockwell also offer 3-year warranty for their oscillating tool.

How oscillating tool works?

As the name suggests, an oscillating tool works by oscillating a blade by a certain degree called oscillation angle by a certain speed measured in oscillations per minute to reproduce the action of a human hand making small repetitive cuts with a miniature saw. The oscillating tool just does that at around 20,000 oscillations per minute with oscillation angles ranging from 1 to 5 degrees. It is basically sawing the material it is being used on with very small strokes but at an extremely fast speed.

Are oscillating tool blades universal?

Many brands make universal oscillating tool blades and accessories where universal means that they will be compatible with oscillating tools of other brands as well. Similarly, oscillating tools themselves can either have a universal built-in fitment mechanism to allow compatibility with blades of other brands such as Rockwell Sonicrafter F30 and F80, Milwaukee 2426-20 and 2626-20, Avid Power ADMT146, Porter-Cable PCC710B and Genesis GMT15A oscillating tools in our research.

Alternatively, many brands make universal accessory adapters for their oscillating tools. After installation of these adapters on the tool, it is able to work with blades and accessories of other brands as well. For example, DEWALT makes such adapter for oscillating tools DCS356, DWE315K and DCS354B. Makita XMT03Z and Ryobi P340 also have the referred adapters.

Some tools can have compatibility issues with blades and accessories of other brands for example Fein MultiMaster Oscillating Multi-Tool Model FMM350QSL has a special Starlock touch-free fitment design that does not accept blades and accessories of even Fein’s own blades and accessories from other product lines.

In short, you must always check the product review pages and FAQs section to find if a particular model of oscillating tool works with a blades and accessories of a particular brand.

Is an oscillating tool worth it?

An oscillating tool fulfills the spectrum of requirements that fall between very delicate work and heavy-duty work. On one end, a Dremel tool is used for making minute cuts, trims and perform grinding and sanding on miniature objects.

One the other end, reciprocating saws and circular saws are used for comparatively heavy-duty cutting applications. An oscillating tool is designed for fulfilling all of the requirements that fall in between these two extremes and it is definitely worth it for such applications.

For example, in your home renovation project, you want to cut square holes in drywall or sheetrock for installation of electrical sockets. It is not worth it to buy a reciprocating saw for such a small task when you can get the job done with he help of an oscillating tool fit with a plunge cut saw blade for wood.

At the same time, you may want to smooth out some rough edges of a piece of furniture. It is definitely not worth it to buy a palm sander for such a small sanding job. An oscillating tool will take care of it easily.

Other Articles You May Like

brizy_dc_post_title

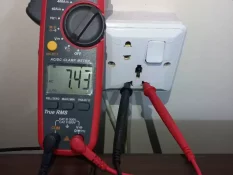

We explain how to test outlet with multimeter (or clamp meter) in 10 simple steps elaborated with pictures.

brizy_dc_post_title

We explain the difference between Milling and Welding - two manufacturing processes used for making stuff.

brizy_dc_post_title

Intro to welding skid with examples of custom made welding skids for pickup trucks & flatbeds. We also give important design considerations.

brizy_dc_post_title

We discuss the most important factors in selection of oscillating tool and answer some FAQs along the way.