Welding Skid Guide - Introduction, Ideas & Important Design Considerations

A welding skid is simply a metallic structure over which a welding plant and its accessories are installed. The frame is designed to fit in a pickup truck or flatbed truck. Once the welding equipment with its necessary accessories is installed over the welding skid and fitted on a truck, the truck becomes a mobile welding rig. The welding skid can be mounted or removed from the truck by using a fork lifter, crane or chain hoist.

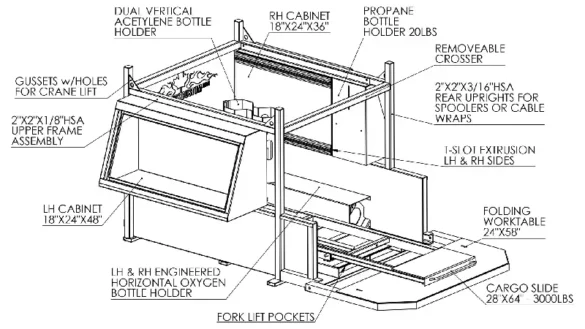

A Welding Skid Design

(Image Courtesy of RivalTruck.ca)

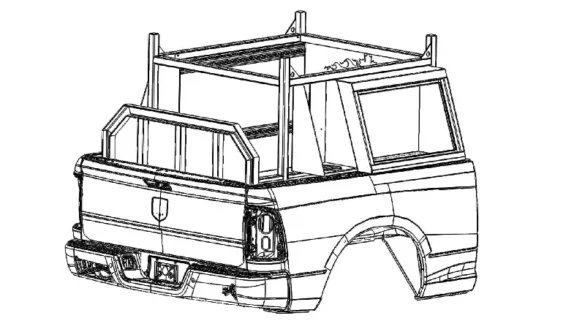

A Welding Skid design depicting how it will be mounted on the truck

(Image Courtesy of RivalTruck.ca)

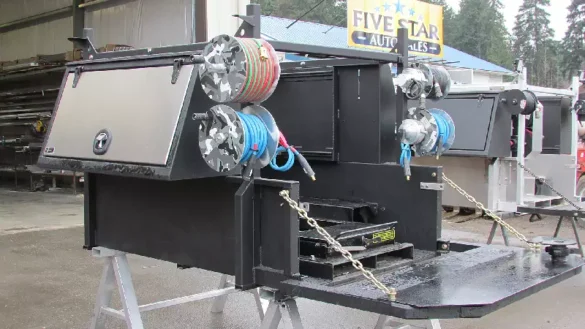

Design converted into reality

(Image Courtesy of RivalTruck.ca)

Welding Skid mounted on the truck

(Image Courtesy of RivalTruck.ca)

Welding skids are generally used by welding contractors to eliminate the hassle of transporting their welding equipment and accessories individually on each job. It is much easier to have the welding plant and its accessories mounted over a welding skid in an organized manner than to have them placed in the trunk individually on each job. With a welding skid, welding contractors are able to make sure that they are always carrying their equipment on the job with nothing left behind.

Welding skids allow welders to have their welding equipment and accessories stored in a very organized way. They can fetch whatever they need from over the welding skid and place it back once it has been used. By the end of the job, there will be no need to gather the tools and equipment from site as welding skid will have everything over it ready to be taken home.

Welding skids generally have at least the following basic welding equipment mounted over them:

- Electric welding plant

- Hooks for welding cables

- Welding gas cylinders

- Hooks for welding gas hoses

Therefore, the most basic design of a welding skid will have storage for the above basic equipment.

Welding Skid Ideas

While welding skids generally have the above mentioned equipment mounted over them, there are no hard and fast rules in welding skids with respect to what can they have mounted over them. Welding skids are very customized to the user requirements. The variety in the design of the welding skids is based on what additional accessories and tools can it store apart from the basic welding equipment mentioned above.

Welding skids can have:

- Built-in toolbox to store auxiliary tools used by welders such as pipe clamps and pipe vise, angle grinder, die grinder, measuring tape and other hand tools

- A dedicated storage for a fire extinguisher

- Jack stand holders

- A dedicated shelf for storage of PPEs such as welding safety helmet, safety goggles and safety gloves

- Reels for welding cables and hoses instead of hooks

A Custom Made Welding Skid for Pickup Truck

Just to spring some ideas of welding skids, take a look at this custom-made welding skid for Pickup Truck Model GMC Sierra 1500. This welding skid has:

- 2 storage boxes

- 3 reels for welding cables and hoses

- A flat metal table for welding jobs

- 3 gas cylinder holders (one each for argon, C25 and acetylene)

- 2 platform gratings over the welding skid, one over the truck’s trunk and the other over the truck’s cabin, for loading up some extra material

Tidbit

C25 refers to the commonly used shielding gas in welding. It is 75% Argon gas and 25% Carbon Dioxide gas by composition.

(Video Credit: YouTube Channel “Max”)

A Custom-made Welding Skid for Flatbed Truck

As another example, take a look at this welding skid idea below made for an old flatbed truck model Ford F-350. It has the following main design features:

- 5 welding gas cylinder holders (2 for Oxygen gas, 1 for Acetylene, 1 for C25 and 1 for Argon)

- 4 hooks for looping welding cables and hoses (including a 150 ft. cord, a 125 ft. stinger lead, another 125 ft. ground lead and a 100 ft. oxy-acetylene welding hose)

- 2 Jack Stand holders

The welding skid layout on this flatbed trailer leaves a 4 ft. x 7 ft. area of the flatbed vacant to be used as a solid fab table.

(Video Credit: YouTube Channel “Welderbeast LLC”)

Some More Welding Skid Ideas

Welding Skid with reels and storage shelves

(Image Courtesy of RivalTruck.ca)

Welding Skid with hood and a large sliding toolbox

(Image Courtesy of RivalTruck.ca)

A very simple welding skid with just a platform and reels

(Image Courtesy of RivalTruck.ca)

Welding skid with fire extinguisher, reels and cabinets

(Image Courtesy of RivalTruck.ca)

Welding Skid Size & Dimensions

While welding skids can be made of any size required by the user to fit the truck in which the skid is to be installed, welding skid size and dimensions can be divided into two broad categories:

- Short Box Welding Skid

- Long Box Welding Skid

The short box welding skids are designed for smaller truck bed sizes with the standard length of cargo box around 6.5 ft. such as in the standard bed size variant of Chevrolet Colorado and Ford Super Duty truck.

A short box welding skid

(Image Courtesy of RivalTruck.ca)

The long box welding skids are designed for long truck bed sizes with standard length of cargo box around 8 ft. such as the long bed variants of the Chevrolet Silverado, GMC Sierra 1500 and the Ford F-150.

A long box welding skid

(Image Courtesy of RivalTruck.ca)

The width of both the short box welding skids and the long box welding skids generally remains approximately 5 ft. to fit the width of the trucks cargo boxes. However, the extra 1.5 ft. of length in the long box welding skids allows for more accessory holders, cabinets and storages to be incorporated into the welding skid design. Alternatively, the same space can be used as a fab table for welding.

Important Things to Remember in Welding Skid Design

Whether you are building your own welding skid or buying a premade one, there are some important design features you must look for.

First is that the paint job on a welding skid is critical to its long life. Since welding skids will face dust, debris, dirt, rain and other external environment factors, it is recommended that a good enamel weatherproof paint is applied on the welding skid.

Second, those components of the welding skid that are not bearing the load of welding equipment such as the welding skid toolboxes and welding skid cabinets may be made of aluminum for reducing weight and eliminating chances of rusting. Welding skid cabinets must also have a good rubber gasket to prevent dust and moisture from entering inside.

While it might appear that a fully loader welding skid is heavy enough to sit firmly on the truck, there must always be good fastening between the welding skid and the truck. The last thing you’d want is your welding skid sliding under a braking action of the truck causing an accident or at least scratching your truck’s cargo floor.

The cylinder holders on a welding skid will produce clinking with the gas cylinders inside them during truck movement, especially in rough terrain. Similarly, other holders such as the jack stand holders and even the hose and cable hooks (or reels) need to be designed with consideration to this clinking. It is best to use rubber paddings wherever possible to reduce metal to metal contact.

Welding Skid Mounting & Removal

The welding skid fully loaded with all the welding equipment and accessories can be loaded (or unloaded) into the truck with the help of a hoist crane or fork lift truck. Once placed over the truck cargo box with the help of crane/fork lift, it can be slid into place with manual force.

Since welding skids are heavy, safety must be given its due consideration. Safety here refers to the safety of personnel and the safety of truck over which the welding skid is being mounted.

If you like our post and the information we have presented, please do give your valuable feedback and share this article with your friends.

Other Articles You May Like

brizy_dc_post_title

Learn about Autonomous Maintenance - part of Total Productive Maintenance that empowers machine operators in basic maintenance tasks.

brizy_dc_post_title

Learn what is RAMS - acronym of Reliability, Availability, Maintainability & Safety/Supportability - in industrial maintenance.

brizy_dc_post_title

We explain what is the supposed role of Maintenance Planning Department in industry. We clear misconceptions and give do's and don'ts.

brizy_dc_post_title

Explaining 6 industrial maintenance types: Preventive, Reactive, Corrective, Predictive, Proactive and Reliability Centered Maintenance.

brizy_dc_post_title

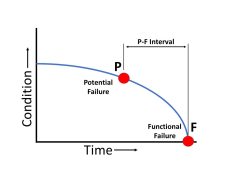

Practical aspects of PF Curve and PF Interval in maintenance & reliability explained. Learn what's the most important question in PF interval?

brizy_dc_post_title

The practical application of ABC classification of inventory for maintenance spare parts with examples from different industries.

brizy_dc_post_title

We explain the concept of Inherent Reliability - A metric used in industrial maintenance and reliability management.

brizy_dc_post_title

Intuitive explanation of Achieved Availability - Metric used in Industrial Maintenance & Reliability Management.

brizy_dc_post_title

Explaining in simple English the term Mean Time To Repair or Replace (MTTR) used in maintenance management.

brizy_dc_post_title

We explain the terms Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) in simple and practical language.

brizy_dc_post_title

We give a detailed example of calculating Overall Equipment Effectiveness (OEE) for HVAC equipment (in a story telling style).

brizy_dc_post_title

Explaining the 8 wastes of lean manufacturing (or lean production) philosophy that are applicable on maintenance management.

brizy_dc_post_title

Intuitive explanation of the difference between Total Effective Equipment Performance (TEEP) & Overall Equipment Effectiveness (OEE).

brizy_dc_post_title

We explain in layman terms what is Overall Equipment Effectiveness (OEE) - a metric maintenance teams aim to maximize in industry.

brizy_dc_post_title

We explain a useful metric that is used by maintenance managers to determine efficiency of their maintenance workforce.

brizy_dc_post_title

We explain the maintenance work order system (or work management system) used by maintenance departments in simple words.