Dewalt DWE7491RS vs Bosch 4100-09 Jobsite Table Saw

Affiliate Disclosure: Handy Tool Adviser is reader-supported. When you buy through links on our site, we may earn an affiliate commission at no cost to you. Read more about our affiliate association here.

Updated: 17-September-2023

The Dewalt jobsite table saw model DWE7491RS and Bosch 4100-09 (upgraded to Bosch 4100-10) are two great competitors for any person looking for a portable table saw solution in their professional or DIY projects.

In today’s post, we have compared these two popular models to ascertain the best option for you to buy in the light of pros and cons of each tool. So, without further due, let’s begin.

Dewalt vs Bosch Table Saw

Comparison in Cutting Capacities

We will start with comparison of cutting capacities offered by both models. By cutting capacity, we mean the specifications that determine the maximum size of workpiece the tools can handle as well as the capacities of making angled cuts.

Parameter | Bosch 4100-09 or 10  | Dewalt DWE7491RS  |

Ripping Capacity | 30" | 32-1/2" |

Blade Size | 10" | 10" |

Table Size | 21-1/2" x 29" | 21-7/8" x 26-3/8" |

Bevel Capacity | -2 to 47 deg. | 0 to 45 deg. |

Depth of cut @ 90 deg. | 3-1/8" | 3-1/8" |

Depth of cut @ 45 deg. | 2-1/4" | 2-1/4" |

Max. Rip capacity to left of blade | 8-1/2" | 22" |

Max. Rip capacity to right of blade | 30" | 32-1/2" |

Maximum Thickness of Wood

Both saws feature a 10” blade with a maximum depth of cut of 3-1/8” at 90 deg. and 2-1/4” at 45 deg. of bevel angle. It means that neither of the tools have any advantage over the other in the maximum thickness of lumber or any other workpiece they can handle. Both saws can handle a maximum of 2x3 lumber.

Ripping Capacity

When it comes to ripping capacity, Dewalt is clearly ahead with a ripping capacity of 32-1/2” vs. 30” of Bosch. Even when comparing the left side, Dewalt wins by offering 22” leeway while Bosch offers only 8-1/2”. In short, Dewalt DWE7491RS will be able to handle larger plywood panels and sheet material as compared to Bosch 4100-10.

It is important to mention that requirement of a ripping capacity greater than 30” from a portable table saw is quite rare. Chances are that if you are running into jobs requiring greater ripping capacities, you would already have a workshop with a large fixed table saw.

Convenience of Handling Large Sheets

Despite having a greater ripping capacity, the overall table size of Dewalt’s saw is smaller than Bosch.

Dewalt DWE7491RS features a table size of 21-7/8" x 26 - 3/8" that makes up a total area of around 4 square feet. On the other hand, Bosch 4100-10 features a table size of 21-1/2” x 29” making up a total area of 4.3 square feet.

The extra working area on Bosch gives it slight advantage over Dewalt in conveniently feeding the job to the saw by improving stability.

Range of Angled Cuts

When it comes to ripping capacity, Dewalt is clearly ahead with a ripping capacity of 32-1/2” vs. 30” of Bosch. Even when comparing the left side, Dewalt wins by offering 22” leeway while Bosch offers only 8-1/2”. In short, Dewalt DWE7491RS will be able to handle larger plywood panels and sheet material as compared to Bosch 4100-10.

It is important to mention that requirement of a ripping capacity greater than 30” from a portable table saw is quite rare. Chances are that if you are running into jobs requiring greater ripping capacities, you would already have a workshop with a large fixed table saw.

Dewalt vs Bosch Table Saw

Comparison in Power

The next parameter for comparing the two saws is power. Both saws offer a 15.0 amp. motor. Bosch has a maximum blade speed of 3,650 RPM while Dewalt has a maximum blade speed of 4,800 RPM.

While it appears that Dewalt has an edge for its higher RPM, the difference in cutting performance is not as stark with both saws being able to cut through lumber, plywood and other common materials with ease.

From the everyday plywood, OSB and pine to white oak, walnut, birch, maple and hickory, these jobsite table saws will get the job done. They will cut anything from the normal baseboards to pressure treated 2x6's with ease.

Whether it is cabinet making, home remodeling, making shims from 2x4's, breaking down full size sheet goods, decking project or making beehive from redwood, both of these table saws fit the job.

Dewalt vs Bosch Table Saw

Comparison in Portability

A jobsite table saw is all about portability. If you didn’t need a portable solution, you would have invested in a standard fixed table saw. Therefore, the convenience of moving the table saw from one jobsite to another holds great importance in this comparison.

Ease of Setting up & Folding

The Bosch 4100-10 has a gravity rise stand that uses the weight of the table saw to your advantage and assists you in folding the unit as well as setting it up. All you have to do is give a little pull to the handle with your hand and the wheel axle with your foot and allow the gravity rise mechanism to set the table saw in place all by itself.

Dewalt has a rolling stand design where the four legs of the table saw have to be opened up one by one to set up the saw. Similarly, the legs have to be folded back separately when folding the saw to make it roll on its wheels.

Bosch’s gravity rise design takes less effort and less time to set up and fold the unit as compared to Dewalt. Moreover, it is comparatively less messy because when you are transporting a table saw from jobsite to jobsite, it tends to get quite dusty and you wouldn’t prefer grabbing the dusty legs to set up your saw.

Bosch's gravity rise design takes advantage of saw's weight to reduce effort in folding and setting up the saw.

Compactness when Folded

One of the important advantages of portable table saws is that you can fold them and store them in a corner of your workshop when there is no use for them. It conserves workshop space. The important aspect with respect to comparison here is how much compact the saw becomes after it has been folded. The more compact it becomes, the more space you save.

Dewalt folds up to a boxed dimensions of approximately 27.5" x 46" x 21-1/2" consuming a total cubic space of 15.8 cubic feet. On the other hand, Bosch 4100-10 folds up to approximately 47" x 30" x 29" consuming a space of 23.6 cubit feet.

Dewalt folds up to a more compact unit than Bosch allowing greater conservation of space with the ability to fit into more confined spaces than Bosch.

Bosch folds up to a total cubic volume of around 23.6 cubic ft.

Bosch folds up to a total cubic volume of around 15.8 cubic ft.

Loading & Unloading in Your Pickup Truck

You would inevitably be loading and unloading your jobsite table saw in your pickup truck while moving from one project to another and the ease of handing the folded unit plays important role in portability of the saw.

None of the two saws have any advantage over the other in this area as both the saws weigh around 90 lbs. and need two people to load them in your pickup truck without a ramp.

Storage of Tools & Accessories

It is not just the saw that moves from one point to another but the tools and accessories that come with it as well. Portability, therefore, includes the ease of carrying these tools and accessories with the unit from one jobsite to another.

Both Dewalt and Bosch offer on-board tool storage where no separate bag or pouch is needed to carry the fence, blade guard, riving knife, push stick and wrenches for blade replacement. All these tools are stored on the unit itself.

Dewalt table saw holds its tools on-board. Bosch has similar functionality.

Dewalt vs Bosch Table Saw

Comparison in Ergonomics

Ergonomics is all about fitting the job to the worker. It includes how convenient is it for the user to make different types of adjustments in the saw to fit the cutting requirement as well as the general feel of using the tool.

Rip Fence Design

Rip fence is going to be the most frequently used attachments to your jobsite saw and how comfortable is it to adjust the rip fence holds great importance in day to day use. What is even more important is that rip fence must remain square with the blade.

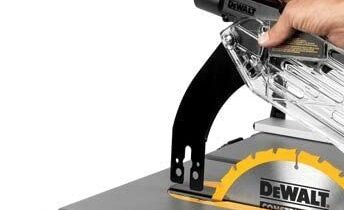

Dewalt has edge over Bosch in rip fence design. It offers a rack and pinion telescoping rip fence design that remains perfectly square while extending and contracting. Bosch features a square lock rip fence design that clamps to the side of the table and slides back and forth to adjust ripping capacity.

Dewalt’s design can be operated easily with one hand wit the help of a rotating knob that allows fine adjustment of the rip fence in a much more firm and square manner. Bosch requires you to adjust the rip fence by applying pressure on both ends of the fence and the sliding is not as smooth and variable as Dewalt’s design.

Dewalt has rack & pinion telescopic rip fence design. It allows convenient extension while remaining perfectly square with the blade.

Bosch clamping fence design locks the fence with the table.

Auxiliary Rip Fence for Narrow Cuts

Both saws feature an auxiliary rip fence for making narrow rip cuts. Dewalt’s auxiliary fence is a flip over design that is slightly more convenient than Bosch.

Ease of Adjustment of Bevel Angle & Blade Height

Both Bosch and Dewalt have similar mechanism of adjusting the bevel angle and blade height that is controlled with the help of a large ergonomic wheel moving in an arc slot. None of the two models have any advantage over the other in this area.

Bosch bevel angle & blade height adjustment mechanism.

Dewalt bevel angle & blade height adjustment mechanism.

Tool-free Adjustments & Replacements

A jobsite table saw will need you to adjust, disassemble and assemble different parts such as the fence, blade guard and anti-kickback pawls (discussed in more detailed ahead in this post). It is much more convenient when no tools are required for assembling and adjusting these accessories. Dewalt and Bosch both have majority of these adjustments tool-free.

However, Bosch has an advantage when it comes to blade replacement as Bosch features arbor lock while Dewalt doesn’t. Arbor lock on Bosch allows you to use only one wrench to remove and replace the saw blade. With Dewalt, you’ll have to lock the arbor with one wrench while removing the nut with the help of another.

Noise Level

While neither of the two brands have specified the noise level rating of their saws, Dewalt DWE7491RS is louder in operation than the Bosch. We found multiple user complaints on the Dewalt being very loud which is partly attributable to its much greater rotary speed 4,800 RPM that is considerably greater than Bosch’s 3,650 RPM rating.

Cord Length

None of the two models have any advantage over the other on cord length as both feature 6 ft. length of power cord. You will need an extension with both saws in most of the cases unless you move the saw around only in your workshop with a power receptacle in close proximity.

Housekeeping

Since table saws produce lots of saw dust, another important feature is a dedicated port for attaching a vacuum or dust extraction system to keep your workshop or garage clean while working.

Both Dewalt and Bosch provide a dedicated 2-1/2” dust collection port in their saws to allow you to attach your dust collection system while working and save yourself from picking up a broomstick to clean your workshop afterwards.

Dewalt 2-1/2" dust extraction port. Bosch has similar port.

Levelling on Uneven Surface

Quite often you run into a situation where your surface in which you are setting up your jobsite table saw is not perfectly level, especially when working outdoors. Under such a scenario, it becomes important that your unit has feet with adjustable level.

Bosch has included this feature in its jobsite table saw where you can vary the height of the two feet to adjust them to the surface level in a way to make the table of the saw perfectly horizontal, however, Dewalt’s feet are not adjustable.

Bosch features height adjustable feet to level it on uneven surfaces.

Bosch vs Dewalt Table Saw

Comparison in Safety Features

Rotary saws are potentially dangerous tools that can cause serious injury in case of any mistake or misuse by the user. It is important that a jobsite table saw is fitted with modern safety features developed to save user in case of any forgetful action.

Both Bosch and Dewalt offer the following safety features,

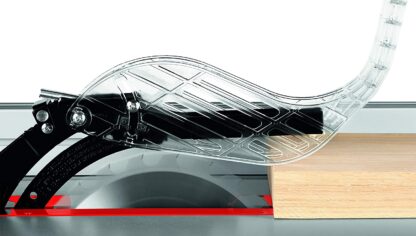

1. A translucent blade guard that covers the blade and prevents user’s hand or any object other than the workpiece from coming into contact with high speed rotating blade.

Bosch transparent blade guard.

Dewalt transparent blade guard.

2. A riving knife that keeps the kerf open to prevent the workpiece from pinching the saw blade and potentially creating a kickback scenario.

Bosch riving knife.

Dewalt riving knife.

3. Anti-kickback pawls, or as Dewalt calls it anti-kickback assembly, is a pair of fixtures that hang on the outfeed side of the saw with teeth angled in such a way as to slightly dig into the workpiece if the workpiece tries to move in the opposite direction – a kickback scenario.

Bosch anti-kickback pawls. Dewalt calls it anti-kickback assembly.

4. A large power OFF switch mimicking an emergency stop button with a concealed ON switch. It makes turning OFF very easy and obvious while turning the saw on is a little difficult and requires more attention. It ensures that the saw is not turned on accidentally, while at the same time, turns off with slightest of effort.

Dewalt ON/OFF switch.

Bosch ON/OFF Switch.

Bosch vs Dewalt Table Saw

Comparison in Maintenance & Longevity Features

Both of the saws require minimal maintenance and nothing out of the ordinary such as lubrication and servicing of hinges and adjustment mechanisms over time, however, Bosch has one great feature that Dewalt doesn’t have.

Bosch gives a motor soft start feature in its saw that is an electronic control system that gradually revs up the saw blade to its top speed. It reduces the startup current drawn by the saw from the power source as well as reducing jerk that motor assembly experiences in case of a sudden speed spike. It not only saves your breaker from tripping at startup but also improves tool life.

Bosch vs Dewalt Table Saw

Comparison in Package Contents

Both Dewalt DWE7491RS and Bosch 4100-10 come with a 10” carbide tipped blade, push stick, miter gauge, rip fence and adjustment wrenches. However, the stock miter gauge on both saws does not firmly lock the miter angle – a problem openly expressed even in good reviews for both the saws.

Bosch vs Dewalt Table Saw

Comparison in Brand’s Product Support

Jobsite table saws are not cheap products. They are noticeable investments and the support provided by manufacturer especially in the form of warranty plays an important role in securing your investment.

Bosch offers its 1 year standard warranty for 4100-10 while Dewalt offers its standard 3 year warranty with 1 year free service including replacement of parts worn out through normal use free of charge as well as 30 days money back guarantee if you are not satisfied with the product. There is no question that Dewalt’s product support is much better than Bosch for its jobsite table saw.

If you are interested in learning more about product support offered by different brands, we have a dedicated post on comparing power tool brands where product support is one of the main comparison factors. You can read it here.

In a Nutshell

Dewalt has better rip fence design and product support for its DWE7491RS jobsite table saw as compared to Bosch while Bosch is ahead of Dewalt with its gravity rise stand, motor soft start feature, greater table size and larger bevel angle range. The Bosch is ahead of Dewalt is overall ergonomics of the tool.

Final Recommendation

Given the overall advantage of better ergonomics and user experience with Bosch, we recommend Bosch 4100-10 as the better of the two options. However, Dewalt is the more economical and readily available model (Bosch is hard to find these days).

If you like our post and the information we have presented, please share this article with your friends.

Other Articles You May Like

brizy_dc_post_title

We explain the difference between Milling and Welding - two manufacturing processes used for making stuff.

brizy_dc_post_title

To find the best spotlight for long distance, we rank 12 popular models while giving application-wise recommendations along the way.

brizy_dc_post_title

Intro to welding skid with examples of custom made welding skids for pickup trucks & flatbeds. We also give important design considerations.

brizy_dc_post_title

We look into the history of power tools industry to trace when the top brands were born and when important power tools were invented.

brizy_dc_post_title

From Fein to Makita, we compare 15 popular models for finding the best oscillating tool based on common applications.

brizy_dc_post_title

A detailed look into the use of brushless motor technology in power tools and comparison of tangible vs. theoretical advantages.

brizy_dc_post_title

Are you looking for the best chop saw for the money? In this post, we compare 7 popular models to find the best chop saw for metal.

brizy_dc_post_title

Dremel 8220 to Dremel 4300, we find the best dremel tool for your application from as well as the best rotary tool alternative to Dremel.

brizy_dc_post_title

We bring a complete guide on torque wrench calibration from the basic concept of calibration to calibration certificates, we explain it all.

brizy_dc_post_title

We research the market to bring you the best impact driver for mechanics, woodworking, construction, HVAC and DIY applications.

brizy_dc_post_title

Our top picks for the best miter saw stand for each of professional, DIY, heavy duty and light applications from Bosch and Dewalt to Toughbuilt and Bora.

brizy_dc_post_title

Our top picks for the best brad nailer cordless & pneumatic for woodworking including baseboards, cabinets, trims, quarter rounds, crafts and DIY.

brizy_dc_post_title

We find the best torque wrench for different applications as cost effective alternatives to the premium Matco & Snap on torque wrench.

brizy_dc_post_title

Our take on the best hammer drill for applications ranging from construction work, concrete drilling & screwdriving anchor bolts to home use and DIY.

brizy_dc_post_title

Our recommendations on the best wire strippers for electricians, electronics technicians, HVAC technicians, auto electricians, DIYers & homeowners.

brizy_dc_post_title

We compare 9 models to find the best cordless circular saw for home use, professional use, framing and roofing.