Best Torque Wrench for the Money - Top Picks by Application

Affiliate disclosure: Handy Tool Adviser is reader supported. When you buy through our links, we receive a small commission at no additional cost to you.

Premium brands like Matco and Snap-on make the best torque wrench with respect to accuracy and reliability, however, they are the most expensive torque wrenches in the market. If you are here reading this post, you are looking for a cost effective alternative to these premium tools.

We have conducted a thorough market survey to find the best torque wrench for each of the most common applications including general automotive repair work of motorcycles, cars and jeeps; tightening of lug nuts; automotive engine overhauling and rebuilding; overhauling of small to medium size generators and repair of electrical equipment, HVAC equipment and general home appliances.

Torque wrenches have two basic parameters of selection i.e. drive size and torque range. Combinations of these parameters decides the fitness of a torque wrench for a particular application, therefore, we have categorized our recommendations accordingly.

Don’t forget to read a short discussion on why torque and torque wrenches matter at the end of the rankings. We are sure you’d find it insightful.

Our Top Picks at a Glance

Drive Size 1/4"

These are small torque wrenches used for small fasteners such as oil pump cover screws, oil cooler bolts and bracket bolts of motorcycle's power unit.

Drive Size 3/8"

These torque wrenches will cover majority of small to medium size screws and bolts in automotive assemblies such as muffler bolts, spark plugs, engine generator rotor bolts and engine oil drain bolts.

Drive Size 1/2"

These torque wrenches will cover comparatively larger screws and bolts such as lug nuts, driveshaft castle nuts and strut assembly mounting bolts.

Best 1/4" Torque Wrench for the Money - Top 3 Picks

The 1/4" drive size is used for small fasteners such as oil pump cover screws, oil cooler bolts, generator cover bolts, clutch spring and cover bolts, coolant drain bolts and bracket bolts of motorcycle power units. These torque wrenches come in in-lb scale because of the smaller range of torque values they have to handle. We found the following three torque wrenches to be good value for money in the 1/4" drive size,

1. CDI Click Type Torque Wrench Model 1501MRMH (20-150 in-lb.)

Our Rating: 8.8 / 10

CDI is subsidiary of Snap-on and provides high quality tools at comparatively lower prices than Snap-on tools. This 1/4" CDI torque wrench features a beam length of around 10" that is a good combination of compactness for fitting in tight places and leverage for ease in tightening screws. Torque is adjusted in 1 in-lb increments.

To give some examples of its use, this torque wrench will install new clutch and brakes as well as torque the valve cover on your 2000 Honda Prelude. It will safely torque the aluminum fasteners on your car that are easy to damage by over-torquing so you can use it for assembling automobile engine's M6 screws into aluminum threaded holes without a worry.

It will also take care of your motorcycle maintenance, dirt bike maintenance or repairing your carbon fiber bicycle. Some people have given positive feedback of its use even in maintenance of private aircraft. In short, it is a great choice for any professional or home mechanic looking for torquing light duty fasteners.

It complies to ASME B107 standard for performance and safety requirement of torque wrenches and comes with a dated calibration certificate, however, the calibration certificate tests it in 30-150 in-lb range.

Lifetime warranty provided by CDI is the best warranty in competition making it our top pick as the best torque wrench for the money based on its accuracy, certification and compliance to standards.

Pros

Shortcomings

Tidbit

We used the term ASME above. ASME stands for American Society of Mechanical Engineers. Headquartered in New York City, ASME is a not-for-profit organization that publishes standards and guidance documents in the area of mechanical engineering. Compliance to their standards is not mandatory by law but voluntary. However, compliance to ASME standards expresses proactive approach of the manufacturer towards high quality standards for its products.

2. GEARWRENCH Click Type Torque Wrench Model 85060 (30-200 in-lb.)

Our Rating: 8.4 / 10

GEARWRENCH has made a good reputation in the industry for providing quality tools at a reasonable price. This 1/4" drive torque wrench works in 30-200 in-lb. range with a beam length of 12" and torque adjustment increments of 1 in-lb.

It features a reversible ratchet, however, measures torque in clockwise direction only.

It is a great choice for working on European made bikes, transmission rebuilds and for working on aircrafts (due to its small profile allowing it to work in confined spaces).

Like CDI, GEARWRENCH also meets or exceeds ISO 6789 and ASME B107.300-2010 standards and specifications on performance and safety requirement of torque wrenches.

Overall it is a good tool with reliable accuracy for working in general mechanical, electrical and automotive applications.

No. of ratcheting teeth could not be traced for this tool, however, its swing per click is slightly larger than desired for working in restricted spaces.

Pros

Shortcomings

3. TEKTON Click Type Torque Wrench Model TRQ21101 (10-150 in-lb.)

Our Rating: 8.4 / 10

TEKTON ties with GEARWRENCH in our rating with its 8.8" beam length, 1 in-lb torque adjustment increments and the ability to measure torque in both clockwise and anti-clockwise direction.

TEKTON gives the best support with its lifetime warranty without receipt of purchase and it would've received a higher rating in our list if conformance to ISO/ASME standards was traceable and if a calibration certificate was provided with the tool.

It will come in handy for tightening plastic parts and small screws in your quad bike maintenance or for your mountain bike repairs. It will install fuel injectors, spark plugs and transmission pan for mechanics or rebuilding the old turbo. It will be useful for maintenance of lawn equipment by homeowners and will also serve gunsmiths for repairing firearms.

Apart from some complaints about its 'click' being too subtle, it is the best torque wrench for the money for motorcycles, bikes and cars. Combining this torque wrench with another of 3/8" drive size, the set will take care of majority of everyday applications in a workshop.

Pros

Shortcomings

Best 3/8" Torque Wrench for the Money - Top 3 Picks

The 3/8" drive size is used for small to medium size fasteners on electrical, mechanical and automotive equipment for example brake caliper screws, engine connecting rod screws, cylinder head bolts, oil pump screws, flywheel and clutch pressure plate bolts.

These torque wrenches generally come in ft-lb scale. We found the following three torque wrenches to be good value for money in the 3/8" drive size,

1. CDI Click Type Torque Wrench Model 1002MFRMH (10-100 ft-lb.)

Our Rating: 9.0 / 10

As stated earlier, CDI is subsidiary of Snap-on and provides high quality tools at comparatively lower prices than Snap-on tools. This 3/4" CDI torque wrench features a beam length of around 16" that provides adequate leverage to the user. Torque is adjusted in 1 in-lb increments and it measures torque in both clockwise and anti-clockwise direction.

It complies to ASME B107 standard for performance and safety requirement of torque wrenches and comes with a dated calibration certificate, however, the calibration certificate tests it in 20-100 ft-lb range.

In this regard, some complaints about accuracy have been observed in the lower torque range but as long as you follow the famous 20-80% rule of torque wrenches, it is accurate.

From tightening lug nuts and motor work for home mechanics to car rebuilding for hot rodding, this tool has got you covered.

Lifetime warranty provided by CDI is the best warranty in competition making it our top pick as the best 3/8" torque wrench for the money based on its accuracy, certification and compliance to standards.

Pros

Shortcomings

2. Precision Instruments Split Beam Click Type Torque Wrench Model PREC2FR100F w/Flex Head (20-100 ft-lb.)

Our Rating: 8.0 / 10

The split beam type torque wrench by Precision Instruments features a tool length of around 17" for good leverage but in 2 ft-lb torque adjustment increments.

This tool has two specialties that makes it standout above competition. First is that its adjustment knob features a dial like design with no spring tension to fight against and no worries about the adjustment getting disturbed because of your grip on the handle during work - a typical problem with micrometer type torque wrenches.

Secondly, this tool does not have to be 'turned down' after use to preserve its calibration - another convenience not available with micrometer type torque wrenches.

To give an idea of its use, it will torque brake caliper pins, suspension parts, lug nuts and help any mechanic or DIYer in engine and suspension reassembly (like torquing the engine head bolts). It will also be useful for bike maintenance like torquing Harley ironhead bolts.

Backed by 1 Year warranty, it is a great value addition to automotive and general mechanical toolkit.

Pros

Shortcomings

Tidbit

We referred to 'turning down’ a torque wrench above. Since micrometer torque wrenches have a spring mechanism inside, it is recommended that when not in use, it should be turned down to its lowest setting to preserve its accuracy. It is important because keeping its spring loaded for prolonged periods of time can cause it to loose its calibration quickly.

3. LEXIVON Click Type Torque Wrench Model LX-182 (10-80 ft-lb.)

Our Rating: 7.5 / 10

The LEXIVON LX-182 comes with a beam length of over 24" that gives great leverage for easy tightening of bolts, it measures torque in clockwise direction only.

Its torque adjustment increments are a little coarse at 2.5 ft-lb, however, its range of 10-80 ft-llb covers a wide variety of bolts and screws. With both ft-lb and Nm scales available on the tool, you won't require a conversion table.

It is a great tool for any home bicycle workshop, weekend mechanics and home owners. From tightening the brake calipers and spark plugs to water pump replacement and working on outboard motor head, this tool is a great choice. It will also help a hobbyist build that racing go kart motor.

There is some negative customer feedback about its click being too subtle, however, if you are not a professional and don't use torque wrench on a regular basis, this is a great tool at a very low price.

Pros

Shortcomings

Best 1/2" Torque Wrench for the Money - Top 5 Picks

The 1/2" drive size is used for comparatively larger fasteners on electrical, mechanical and automotive equipment for example lug nuts, driveshaft castle nuts, strut assembly and brake caliper housing bolts of off-road vehicles. We found the following five torque wrenches to be good value for money in the 1/2" drive size,

1. CDI Click Type Torque Wrench Model 2503MFRMH (30-250 ft-lb.)

Our Rating: 9.1 / 10

CDI comes up again at top with its 1/2" torque wrench that features a beam length of around 24" that provides good leverage to reduce user effort. Torque is adjusted in 1 ft-lb increments and it measures torque in both clockwise and anti-clockwise direction.

It complies to ASME B107 standard for performance and safety requirement of torque wrenches and comes with a dated calibration certificate.

This torque wrench will not just tighten the lug nuts of your car but of your truck, travel trailer and tractor also. Whether you are looking to install rear axle nut back on your Ducati Monster 1200 or installing disc brake frame on your Chevy truck, this tool has got you covered.

In fact, it will do much more than just installing disc brake on your truck. It will work for draglinks, tie rod ends, ARP studs and kingpins as well.

Lifetime warranty provided by Snap-on for its subsidiary's tool combined with its accuracy and reliability makes it our top recommendation as the best 1/2" torque wrench.

Pros

Shortcomings

Tidbit

We used the term ARP Studs above. ARP refers to Automotive Racing Products. It is the name of a manufacturer based in United States that specializes in making engine bolts for automotive racing applications. They have developed a good reputation for making reliable fasteners used in automobiles.

2. Precision Instruments Split Beam Click Type Torque Wrench Model PREC3FR250F w/Flex Head (50-250 ft-lb.)

Our Rating: 8.4 / 10

This split beam type torque wrench by Precision Instruments features a tool length of around 22" for good leverage but the increments are a little coarse at 5 ft-lb.

Like its 3/8" model, this tool also has two specialties that makes it standout above competition. First is that its adjustment knob features a dial like design with no spring tension to fight against and no worries about the adjustment getting disturbed because of your grip on the handle during work - a typical problem with micrometer type torque wrenches.

Secondly, this tool does not have to be 'turned down' after use to preserve its calibration - another convenience not available with micrometer type torque wrenches.

From weekend mechanics working on their RVs and trucks to professional automotive mechanics, this tool will take care of heavy duty jobs. From doing lug nuts to torquing the balancer bolt during procharger installation, this tool will get the job done.

Overall, it is a very good torque wrench for automotive workshops and mechanics.

Pros

Shortcomings

3. GEARWRENCH Click Type Torque Wrench Model 85066 (30-250 ft-lb.)

Our Rating: 8.2 / 10

Another GEARWRENCH model appears on our list with good performance at a reasonable price. This 1/2" drive torque wrench works in 30-250 ft-lb. range with a beam length of around 24" and torque adjustment increments of 2 ft-lb that is a little coarse.

It features a reversible ratchet, however, measures torque in clockwise direction only. GEARWRENCH meets or exceeds ISO 6789 and ASME B107.300-2010 standards and specifications on performance and safety requirement of torque wrenches.

From automotive car, truck and trailer work to mechanical joint fittings and industrial compressor repairs, this torque wrench fits variety of uses. Whether you have a Ducati or a Tacoma, this torque wrench will be a valuable addition to your toolbox.

Overall it is a good tool with reliable accuracy for working in general mechanical, electrical and automotive applications.

No. of ratcheting teeth could not be traced for this tool, however, its swing per click is slightly larger than desired for working in restricted spaces.

Pros

Shortcomings

4. TEKTON Click Type Torque Wrench Model 24340 (25-250 ft-lb.)

Our Rating: 7.9 / 10

TEKTON 24340 features 18.5" beam length for good leverage; 1 ft-lb torque adjustment increments with provision of measuring torque in both clockwise and anti-clockwise direction.

With its lifetime warranty without receipt of purchase, TEKTON gives the best support and it would've been a plus if conformance to ISO/ASME standards was traceable and if a calibration certificate was provided with the tool.

From the occasional axle nut and brake calipers of your truck to the torquing of your trailer's lug nuts before and after each trip, this torque wrench has got you covered. It will work on suspensions, cylinder heads, fuel injectors and any other heavy duty bolts worked by mechanics.

As far as customer feedback is concerned, there have been some complaints about its click being too subtle, however, there have been lots of positive feedback for using this tool on cars, jeeps and tightening lug nuts that makes it the best torque wrench for the money for tightening lug nuts and general car repairs.

Pros

Shortcomings

5. LEXIVON Click Type Torque Wrench Model LX-184 (25-250 ft-lb.)

Our Rating: 7.5 / 10

The LEXIVON LX-184 comes with a beam length of over 24" that gives great leverage for easy tightening of bolts, it measures torque in clockwise direction only.

Its torque adjustment increments are a little coarse at 2.5 ft-lb. With both ft-lb and Nm scales available on the tool, conversion table will not be needed.

It will replace the rotors and brake pads whether it is your 2007 Tahoe or the latest Tacoma. It will torque axle nuts, strut mounts, CV joint nuts, wheel hub bearing nuts, RV hitch nuts and weight distribution hitch bolts, U-bolts, engine head bolts and suspension bolts without any complaint.

Its accuracy of clicks and overall reliability may not be good enough for everyday professional use, however, it is very good option at a cheap price for occasional use.

Pros

Shortcomings

Best Digital Torque Wrench for the Money

Digital torque wrenches have made their way in the market. The main appeal of digital torque wrenches lies in their ease of use, however, there is skepticism in the industry about their accuracy and long term reliability. They are also mote delicate and sensitive to environment than mechanical torque wrenches.

Nonetheless, the convenience digital torque wrenches provide can outweigh their cons in a lot of applications and if your application is of such nature, you might have already checked the most expensive electronic torque wrenches made by premium brands in the industry. Just like we made recommendations for cost effective mechanical torque wrenches, we hereby present our recommendation on best digital torque wrench for the money.

GEARWRENCH Electronic Torque Wrench

Our Rating: 8.6 / 10

GEARWRENCH electronic torque wrench models 85076 (3/8" drive) & 85077 (1/2" drive) feature 25" beam length for ensuring good leverage for the user. It measures torque in both clockwise and anti-clockwise direction with electronic torque adjustment increments of 0.1 ft-lb - finer than majority mechanical torque wrenches.

It provides torque measurements in 5 units including ft-lb, in-lb, Nm, kg-m and kg-cm vs. a maximum of two scales provided in mechanical counterparts.

Noticeable complaints include startup problem at subzero temperatures and that the tool powers off if not used after a set period of time that might create hindrance in work where you use torque wrench intermittently.

Pros

Shortcomings

Why Torque & Torque Wrench Matters? – A Layman Peek into the Physics of Nuts & Bolts

Nuts and bolts have been around since the 1800s. In 1841 British Standard Whitworth (BSW) system of standardized nuts and bolts had been introduced. On the other hand, Torque wrench was only invented in 1931 i.e., almost a hundred years after nuts and bolts.

And it is not like the torque wrench became widespread as soon as it was invented. In the earlier decades, torque wrench was used only in precision engineering industries.

As the realization of the importance of tightening nuts and bolts at the right force (and the dangers associated with loose fasteners) trickled down from mechanical design engineers to technicians to the weekend home mechanics, the use of torque wrench gradually spread from precision engineering industries to the automotive workshops to home garages.

Today, the knowledge that lug nuts on your car should be tightened with a torque wrench has become quite common. However, why torquing is so important scientifically? Let us try to give a short and layman explanation.

The purpose of any nut bolt fastener is to clamp two objects together. How firmly are they clamped together depends on how much the bolt has been tightened.

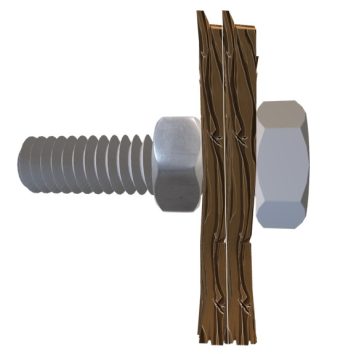

It may be hard to believe for people from non-technical background, but the bolt is flexible and it stretches when you tighten it. In fact, the same stretch is the very reason the whole torque thing actually works.

If the bolt was so hard that stretching did not remain possible, the whole concept of torquing would’ve failed. Let us explain how.

When you tighten the bolt against the nut, you keep tightening until the bolt head touches the surface of the joint being clamped. However, you don’t stop there. You keep turning the bolt with force. The more you turn, the harder it becomes. Why?

It is because now you are trying to push the bolt head against a surface that cannot be compressed. So, what happens? A stretch is produced along the length of the bolt.

Imagine it from the nut’s side. The nut is pulling the threads away from the bolt’s head to try to close the gap between the nut and bolt head. However, if this gap is unable to be reduced (because there is material in between that is being clamped together) but the pulling force keeps on increasing, what will happen?

Bolt will stretch along its length. That stretch is not easily visible as it is produced in tenths of millimeters (depending upon the type and material of the bolt being used). However, if you take a precision measuring tool (like a vernier caliper) and measure the length of the bolt before and after tightening, you’ll notice it has increased.

This stretch is what actually produces the clamping force which is the main purpose of using nut and bolt. Just like a rubber band tries to snap back when stretched, the bolt is also elastic. It tries to snap back.

However, it cannot snap back without the nut being turned. It keeps the bolt in an eternal effort to try to snap back which causes the surfaces in between the nut and bolt to get sandwiched with force. This effort (to try to snap back) is what is technically referred to as ‘the bolt is in tension’.

The elasticity in the bolt material and the stretch produced in the bolt is what creates the clamping force that keeps the jointed surfaces pressed against each other.

But how does this all relate to torque? It is simple.

When you stretch an elastic rubber band, the more you stretch it, the harder it tries to snap back, right?

Same goes with bolts. The more you stretch them (by turning the bolt more), the more tension is created in the bolt material and the harder it keeps the surfaces clamped together.

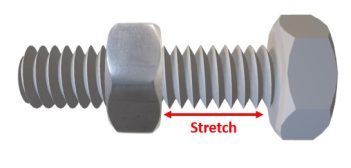

A bolt not tightened as much as needed would not produce the clamping force intended by the mechanical design engineers for keeping two surfaces together in an assembly.

On the other hand, too much tension can snap the bolt’s head off, right? Yes, but there is more. Snapping the head off is an extreme. Something not-so-visible can also happen with too much tension which you might not have considered before.

Too much tension can cause the bolt’s material to escape the elastic limits and enter what is technically known as plastic deformation i.e., the bolt material has been stretched so much that it has lost its ability to snap back and the stretch has converted into a permanent elongation in bolt length.

The above scenario would go unnoticed because the bolt’s head is at its place. However, the bolt is not doing its job despite looking okay. It is not doing its job of clamping properly because the bolt material is not fighting back the stretch anymore as it is supposed to.

This is the reason why torque matters and why torque wrenches are important.

When mechanical design engineers design machine components and assemblies, they also lay down the torque values at which different fasteners have to be tightened. These values are based on what is the clamping force needed without compromising the bolt material.

While every single bolted joint has a torque specified for its bolts, torque wrenches are commonly used in workshops and home garages only for those bolts that are considered critical. For example, lug nuts and engine head bolts.

Even today, the use of torque wrenches is far greater in aviation industry and precision engineering applications than in workshops and home garages.

However, as time passes and awareness of the importance of torquing bolts at the right value spreads, torque wrenches will find use in more hands and places.

How do I choose a torque wrench?

Follow the following steps for choosing the right torque wrench for your needs,

Step-01: Choose the torque range

The number one most important thing in selecting a torque wrench is its working range. To do that, look at your application and select the smallest as well as the largest torque that you need to apply on a bolt or screw. Torque charts are available in service manuals.

An additional consideration in this regard is the famous 20-80% rule for torque wrenches according to which, a torque wrench is most accurate in 20-80% of its full capacity i.e. a torque wrench having maximum rating of 100 ft-lb will practically best work in 20-80 ft-lb range. So whatever torque range you get for your application, use the 20-80% rule to revise your limits.

Step-02: Choose the right drive size

The most common drive sizes for torque wrenches are 1/4", 3/8", 1/2", 3/4" and 1".

1/4" drive size is used for very small fasteners such as those on your bicycle and motorcycle's oil pump cover screws, oil cooler bolts and bracket bolts on power unit.

3/8" and 1/2" drive sizes are the most commonly used drive sizes for everyday machines, equipment and automobiles. 3/8" is for comparatively smaller fasteners such as muffler bolts, spark plugs, engine generator rotor bolts and engine oil drain bolts whereas 1/2" drive size is used on comparatively larger screws and bolts such as lug nuts, driveshaft castle nuts and strut assembly mounting bolts.

3/4" and 1" drive sizes are not commonly used. They are generally used on heavy duty industrial equipment and earth moving machinery.

Step-03: Reconcile the torque range with drive size

Once you have noted down the torque range and drive size for your application, you need to conduct a market survey to ascertain if one torque wrench will fit your need or more than one are needed. Generally, as you move towards more and more technical and professional applications, the harder it becomes to find one torque wrench to fit all needs.

A mechanic will need a 1/4" torque wrench in the range of 2-12 ft-lb for assembling small motorcycle engine and in the same workshop, he will need 1/2" drive torque wrench to tighten lug nuts of a Pickup Truck at 150 ft-lb. A single torque wrench will never satisfy needs laying on two extreme ends. The mechanic will have to pair two torque wrenches to meet his application.

Similarly, you have to ascertain if a single torque wrench will fulfill your need or a set of two to three torque wrenches will be required.

Step-04: What are the torque units you use?

Some torque wrenches only have ft-lb or in-lb units marked over their adjustment scale while others have both ft-lb and Nm for covering both SAE and SI units. If you work on variety of equipment where service manuals specify torque values in different units, it will become inconvenient to consult a torque units conversion chart again and again. Under such case, go for a torque wrench that has both units printed over it to save your time.

Step-05: Check certification and compliance to standards

Since torque wrenches are precision tools, if you are using the use on sensitive equipment there must be some reassurance from the torque wrench manufacturer regarding conformance to standards like ISO 6789 and ASME B107.300 that define minimum requirements a torque wrench needs to meet for safety and performance. Moreover, check if the manufacturer provides a last calibration certificate with the tool as an authentic reference about the last calibration date and accuracy values. If you are not familiar with torque wrench calibration, we've written a complete guide about it for you.

However, you might not need such conformances if your use of the torque wrench is of occasional on-serious nature such as DIY and home use.

Step-06: Check warranty terms

In the tools we have reviewed, CDI and TEKTON give lifetime warranty for their torque wrenches while GEARWRENCH gives 1 year limited warranty and calibration accuracy warrantied for 90 days. LEXIVON gives 1 year limited warranty extendable up to 2 years on product registration. You have to check what warranty terms keeps your mind at ease. We'd recommend going for at least 1 year of warranty.

Step-07: Check ergonomic & bonus features

Torque Measurement in Anti-Clockwise Direction

Majority torque wrenches measure torque only in clockwise direction, however, there are torque wrenches available for measuring torque in anti-clockwise direction as well (such as the CDI 1/4", 3/8" and 1/2" torque wrenches we have reviewed in our post). You have to ask yourself if you need that extra feature?

In general, you don't need an anti-clockwise torque measurement unless you are working on a special piece of machine having left handed screws and bolts. Apart from that, anti-clockwise torque measurement is also needed in technical investigations and research purposes where you might want to check the unscrewing torque of a fastener.

No. of teeth in ratcheting mechanism

How much swing will a torque wrench takes before it clicks? That depends on its no. of teeth in ratcheting mechanism. The more the better because more teeth will allow a shorter swing per click that will enable you to use torque wrench in restricted spots where you can't make a long arc with your torque wrench. If a manufacturer hasn't given information about no. of teeth in ratcheting mechanism, they may be around 20-30 because manufacturers giving more than that generally boast about it but it is better to ask for confirmation. The GEARWRENCH electronic torque wrench and TEKTON 1/4" Click Type Torque Wrench Model TRQ21101 give 72 teeth in their ratcheting mechanism.

Angle Measurement

Some applications require the screws and bolts to be given a certain angle for increased clamping action.

Torque Adjustment Scale Etched or Printed?

Some manufacturers print the torque adjustment scale over metal surface of torque wrench while others etch mark it over the metal. Printed scales can fade over time but etched scales cannot, however, etched scales can sometimes become difficult to read due to being over a glossy surface. The best option is this regard is to go with a scale that is both etched and then filled with paint for added contrast.

Micrometer Adjustment Lock Mechanism

The conventional method used by majority manufacturers to lock the micrometer from rotating unintentionally due to user's grip over the handle during work is to give a screw/knob that once tightened will hold the micrometer in place. However, some manufacturers such as CDI, TEKTON and GEARWRENCH give a locking collar mechanism that is pulled down to adjust the torque and snaps back to lock itself firmly in place. It provides better protection from unintentional disturbance in torque settings.

Socket Removal Button

This small feature comes in very handy in work. Simply press a button to release the socket you have attached with your torque wrench drive. Despite its simplicity, it is not given by all manufacturers.

Once you have gone through these steps, search for the best price you can get and you are ready to go.

Buyer's Guide Questions

Is it OK to loosen bolts with a torque wrench?

Torque wrench is a precision instrument with a sensitive spring tension mechanism that can get disturbed if misused resulting in loss of accuracy of the tool. Loosening a bolt with torque wrench is possible because it has a reversing provision in its ratcheting head, however, it is strongly advised not to use the torque wrench for loosening a screw as it can disturb the tool's calibration and compromise its accuracy.

How do I know if my torque wrench is accurate?

You can check the accuracy of your torque wrench by comparing it with another torque wrench that you trust. There are two possible issues with accuracy i.e. over tightening or under tightening. Follow the following steps for counterchecking the accuracy of your torque wrench,

1. Simply toque a bolt at an arbitrary torque value with the torque wrench whose accuracy is doubtful.

2. Now set the same torque value on the trusted torque wrench and check that bolt's torque.

3. If the trusted torque wrench turns the bolt and then clicks, it means that the suspected torque wrench is under tightening. Note the value and compare the difference.

4. If the trusted torque wrench clicks without rotating the bolt, it means that the suspected torque wrench is over tightening. Increase the torque setting on the trusted torque wrench and see if it clicks. Repeat the process until it clicks and note the value for comparison.

This is the simplest way of roughly checking accuracy of your torque wrench. The professional way is to get its calibration checked from a certified facility.

What is the most common torque wrench size?

3/8" and 1/2" are the most common torque wrench drive sizes used in everyday automotive and general electrical and mechanical applications. However, it is important to mention that the most common size is based on application. 3/8" and 1/2" torque wrenches are generally not used in very small and very large fastener applications. Most common size corresponds to application. Just like 3/8" and 1/2" are most common in automotive and general mechanical repair applications, 3/4" and 1" drive sizes are common in heavy duty industrial applications.

If you liked this post, please share it with someone who may benefit from it.

Other article suggestions