Cordless Circular Saw Selection Guide

Affiliate Disclosure: Handy Tool Adviser is reader-supported. When you buy through links on our site, we may earn an affiliate commission at no cost to you. Read more about our affiliate association here.

How do I choose a cordless circular saw?

Take the following steps in selecting the best cordless circular saw for your requirement,

Step-1: Ascertaining Requirement of Power & Torque

Look at your requirement of power and torque from the saw. Manufacturers generally just give a voltage rating for their cordless circular saws and not power and torque ratings of their motors.

Voltage rating is not a good representative of a saw's ability to cut through tough jobs. Blade size and max RPM must also not be considered as representatives of satisfactory cutting performance.

DEWALT gives max watts out rating for its cordless circular saw DCS570B as 900W that gives an idea of its power, however, majority of the other manufacturers don't give any such rating. Under such case, we recommend that you thoroughly check saw reviews that mention experience with cutting lumber, plywood and drywall etc. to get an idea of how much torque and cutting power the saw carries.

Step-2: Noting Important Safety Features

Look for safety features such as trigger lock (to prevent unintentional tool start), spindle lock (to lock the spindle during blade replacement), electrical brake (to halt the blade as soon as trigger is released) and metallic upper and lower blade guards (to save operator from blade fragments in case of accident).

Step-3: Noting Features to Improve Accuracy of Cuts

Look for features that assist in cutting such as LED light (to illuminate the job), front dust blower (to blow the dust off the cutting line), rip fence (to ensure straight cuts) and laser guide (to add visual cue for straight cutting).

Step-4: Check Housekeeping Aspects

Look for housekeeping features such as rafter hook (for storage and convenience in carrying), onboard blade changing wrench (to eliminate the need for finding a separate tool) and dust port (for hooking up the tool with a vacuum and keep your workplace clean of saw dust).

Step-5: Check Ease of Maintenance

Look for maintenance aspects such as a brushless motor (to eliminate the need of replacement of brushes).

Step-6: Review Warranty Terms Carefully

Look for warranty and always read the terms because the devil is in the details. Milwaukee offers 5 year warranty for its cordless circular saw; DEWALT and PORTER-CABLE offers 3 year warranty with 1 year free replacement of worn out parts (through normal use) and 90 day money back guarantee if user is not satisfied with experience.

On the other hand, some other brands such as Ryobi, SKIL and BLACK+DECKER warrant their products only if they are used in home environment and not professionally.

Therefore, you must always check that warranty of the tool suits you.

Step-7: Check what's included in the package

Last but not the least, you must always check what is included in the package. Brands sell bare tools (tools without battery and charger) separately and complete kits separately.

Bare tools can have a 'B' suffix with their model numbers such as DEWALT DCS570B, BLACK+DECKER BDCCS20B, Bosch CCS180B and PORTER-CABLE PCC660B, however it is not a rule for example Milwaukee, Ryobi and SKIL don't not add such a suffix.

Nonetheless, information about what is included in package is always available. Apart from battery and charger, availability of rip fence and at least one general purpose cutting blade must also be checked.

Step-7: Reconcile & Finalise

Reconcile all your preferences and decide your compromises because no tool will have all the features. You have to make the best choice based on your requirement and cost effectiveness.

Are cordless circular saws worth it?

Ask yourself why cordless circular saws have been invented? They have been developed to offer solution to a problem that lies with corded models i.e. portability. Corded saws limit the user's flexibility to adapt to different work environments.

Contractors working at construction sites without power have to carry generators to power their corded equipment.

Woodworking projects set up only where power is available. Woodworking workshop layouts have an added limitation of positioning work benches near power outlets only.

Cordless circular saws remove all these limitations and give you freedom in work.

The only question that remains is about power. Cordless circular saws are becoming more and more powerful with time replacing corded versions in more and more tough jobs.

Cordless circular saws easily replace corded versions in light to medium duty jobs. Newer cordless models (such as the DEWALT Cordless Circular Saw DCS570B) are replacing corded ones in medium to heavy duty jobs as well.

It is only a matter of time before cordless versions completely replace corded ones, at least in all mobile applications.

So yes, cordless circular saws are definitely worth it because they offer comparable power and cutting performance as corded saws but with added portability and flexibility.

Why are most cordless circular saws left handed?

Most cordless circular saws are left handed (their blade is positioned on left side of the grip) because majority users are right handed users. When they hold the tool in their right hand, a left handed blade configuration gives them a better visual of blade cutting through the cutting line. It results in convenience in making straight cuts.

If you like our post and the information we have presented, please share this article with your friends.

Other Articles You May Like

brizy_dc_post_title

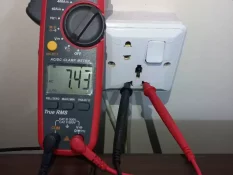

We explain how to test outlet with multimeter (or clamp meter) in 10 simple steps elaborated with pictures.

brizy_dc_post_title

We explain the difference between Milling and Welding - two manufacturing processes used for making stuff.

brizy_dc_post_title

Intro to welding skid with examples of custom made welding skids for pickup trucks & flatbeds. We also give important design considerations.

brizy_dc_post_title

We discuss the most important factors in selection of oscillating tool and answer some FAQs along the way.