What is Inherent Availability in Maintenance & Reliability?

Clarifying Misconceptions & Addressing Knowledge Gaps

Availability (%) is a metric used in industry to express how much work was taken from a piece of equipment vs. how much work could have been taken potentially.

Under this broad definition, there have been multiple definitions of availability. However, the three most widely accepted and used categories or types of availability include:

- Operational Availability

- Inherent Availability

- Achieved Availability

In this article, we will explain what is inherent availability and how it differs from operational availability.

Introduction to Inherent Availability

Availability is a prediction of how much continuous uptime a piece of equipment can offer before a failure. The term “Inherent” refers to the design of equipment. Therefore, Inherent Availability refers to the availability built into the design of the equipment by the manufacturer.

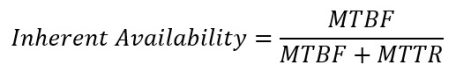

It is expressed by the following formula:

Where,

MTBF = Mean Time Between Failures

MTTR = Mean Time To Repair

So, for example, if a pump has MTBF of 1,000 hours and an MTTR of 2 hours, its Inherent Availability will be 1,000/(1,000+2) = 99.8%.

Who Calculates Inherent Availability? – Not the Maintenance Department!

The simplest thing in the world is to just get a formula, plug values into it and find an answer. That way, you know but still don’t know.

The important thing to understand about Inherent Availability is not in knowing its formula and just running the numbers. The important thing is to be able to understand the physical significance of Inherent Availability.

So, let us do that.

The first thing to always remember about Inherent Availability is that it is calculated by manufacturers of equipment. It is not calculated by maintenance departments or users of the equipment.

When manufacturers are developing equipment, they think of the ways a machine could fail and how much time would repairing the failure take.

Their estimate of how often the machine fails is expressed in the Mean Time Between Failures (MTBF) and their estimate about the time required to restore the machine after each failure is expressed in the Mean Time To Repair (MTTR).

It is very important to remember that since Inherent Availability is calculated at the time of equipment design and development, the Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) come either from simulations or from test facilities in which equipment prototypes are tested.

Sometimes, the manufacturer may start gathering data from the field if the equipment has been put into service. However, even then, the data is of a very short and initial period of the equipment’s service life.

To Understand Inherent Availability is to Understand Its Components

Mean Time Between Failures (MTBF), when calculated by a maintenance department captures the failure rate of equipment over its service life. It covers all the factors that affect machine’s serviceability including how it is operated, how it is maintained, environmental factors and many other.

Therefore, Mean Time Between Failures (MTBF), when calculated by a maintenance organization predicts future probability of a machine failure based on its historical data. The golden word here is historical data.

However, when Mean Time Between Failures (MTBM) is considered for the calculation of Inherent Availability, it is not based on historical data because the equipment hasn’t been put into service yet.

It comes from computer simulations, tests conducted on equipment prototypes and at best, from the limited number of units that may have been put into service recently.

Therefore, the Mean Time Between Failures (MTBM) in Inherent Availability is only an attempt to predict how the equipment will perform in the field. The real Mean Time Between Failures (MTBM) will be revealed only when the equipment is put into service and it faces the challenge of actual operation in a real world environment.

Similarly, the Mean Time To Repair (MTTR) taken in the calculation of Inherent Availability is obtained from tests and assumptions on how the machine will be restored. Therefore, it too is an attempt to predict repair times of equipment under different failures.

Engineers are Never Wrong, Their Assumptions Are!

In all the three types of availability, Inherent Availability is supposed to have the highest value by definition. It is because, Inherent Availability is calculated with the most idealistic assumptions.

Both Operational Availability and Achieved Availability come from actual field data when the equipment is put into real service and it faces the challenges of real world environment.

Therefore, both Operational and Achieved Availability are always meant to be lower than Inherent Availability as actual conditions would never be ideal.

Hence, Inherent Availability is the maximum availability the equipment can have in an ideal world. It cannot be achieved practically. It can only serve as a bar to replace the demand of management to achieve 100% availability.

What Purpose Does Inherent Availability Serve?

We understand that there is a tendency that your takeaway from this article so far could be “if Inherent Availability is all assumptions-based, what practical purpose does it serve?”.

It is a valid question because it is not like folks in industry are coming up with metrics just for the sake of having new metrics. The metrics are purposeful. So, what’s the purpose of Inherent Availability? - Inherent Availability is integral to the design process of a machine.

Just because the new equipment hasn’t been put into service for enough time to get true Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) and calculate a true Availability, it doesn’t end the need for having an idea of availability in the design phase.

If no means of estimating availability at design phase is available, it would mean that the same would be exposed to the manufacturer in the form of complaints from the users.

Design engineers cannot afford to design a machine that would fail frequently when put into service and that takes a very long time to repair. Therefore, they need to foresee future failures and repair times of the machines they are designing.

The above is the purpose that Inherent Availability serves. It allows design engineers to remove defects from the equipment in the design phase and improve the overall reliability and maintainability of the equipment.

With this we conclude our article. If you liked our work, please do share it with someone who would benefit from understanding the concept of Inherent Availability.

If you liked this post, please share it with someone who may benefit from it.

Other suggested articles