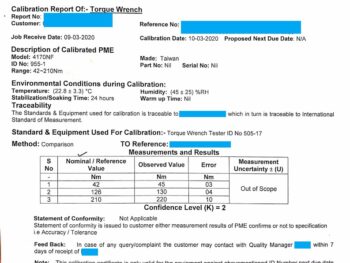

A Guide on Selecting Reciprocating Saw & Its Blades

What should I look for in a reciprocating saw?

There are a lot of specifications of reciprocating saws, however, all of the specifications that a manufacturer is presenting in a brochure or datasheet don’t directly translate to user experience.

Before figuring out what you should look for in a reciprocating saw, you should note down the details of what you are going to use it for. Following main specifications and features play the most important role in user experience,

Look for Portability & Energy Efficiency - Corded vs. Cordless Option

You need to assess if portability is a key factor for you. If it is, you should look for a cordless reciprocating saw preferably with a brushless motor as they are 5-10% more energy efficient than conventional brushed motors and therefore run slightly more before you need a battery recharge.

Look for Compactness - Lightweight & Short Tool That Fits In Tight Spots

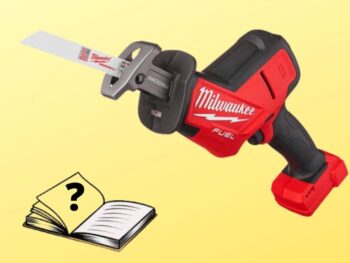

You need to assess if you are going to be working in very tight spaces. If you are, look for compactness in the reciprocating saw you are buying. The most compact saws weigh around 4-5 lbs and have a length of 14-15 inches.

The most compact reciprocating saw we have found is Milwaukee 2719-20 M18 FUEL Hackzall and PORTER-CABLE PCC670B Cordless Reciprocating Saw is the runner up in compactness.

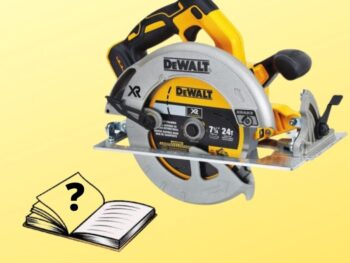

Others that take good points in compactness are DEWALT DCS387B & DEWALT DCS367B Cordless Reciprocating Saw. This compactness will prevent your work from getting hindered just because you can’t reach a tight spot you want to cut.

Look for Vibration Dampening to Reduce User Fatigue

You need to assess if you are going to be using your blade occasionally or frequently. If your use is frequent, vibration dampening mechanism that is generally a counterweight is necessary for preventing excessive vibrations from getting transferred to your hand and shoulder causing user fatigue.

The reciprocating saws we found with good vibration dampening features are Milwaukee 6538-21 Super Sawzall (Corded), Milwaukee 2719-20 M18 FUEL Hackzall (Cordless)and Skil 9206-02 Corded Reciprocating Saw.

A Good Warranty is a Good Insurance Policy

When it comes to warranty, you must read the warranty terms clearly before making the purchase. You must go for at least 2 years warranty because that is easily available with majority manufacturers of reciprocating saws.

- Black and Decker reciprocating saws have 2 years warranty but the catch is that it is valid for home environment only.

- DEWALT and PORTER-CABLE are offering a warranty of 03 years for their reciprocating saws with free replacement of worn out components (covering wear and tear through normal use) for 01 year and a 90 day money back guarantee if the customer is not satisfied with the user experience. This last point is such a big confidence winner that it can easily outweigh a lot of small cons of the machine.

- Milwaukee & Skil are offering warranty of up to 05 years for their reciprocating saws.

Are reciprocating saw blades universal?

Yes. They are universal in the sense that you are not bound to buy blade from the same manufacturer you purchased the reciprocating saw from. Sometimes it happens that one blade might fit better in one reciprocating saw than another in terms of firmness of the fit, however, it is rare that a blade fitting inside one reciprocating saw doesn’t fit inside another of different brand and model.

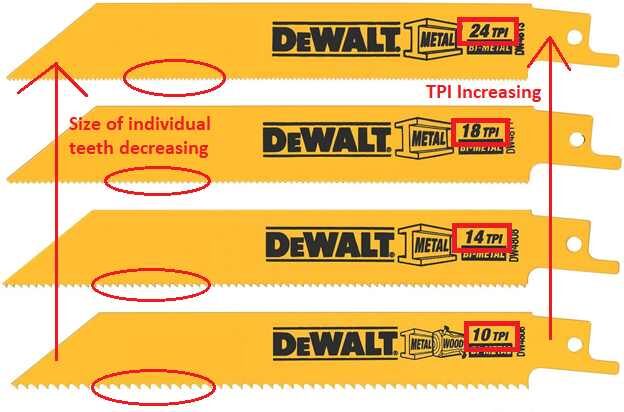

This is not to be confused with the fact that there are different types of reciprocating saw blades for different applications such as metals, wood and demolition etc. The thickness, TPI (Teeth Per Inch) and cutting tip composition (such as a carbide tip for cutting heavy metals) differ in different types of blades based on the application they are designed for.

How many types of reciprocating saw blades are there and how to choose the right blade?

Reciprocating saw blade types are based on their application such as,

- Pruning blades are best suited for cutting tree branches

- Demolition blades are best suited for cutting nail embedded wood

- Metal cutting blades are for cutting light to medium guage metals

- Carbide tip blades are for cutting heavy guage metals

- Combination blades are for multipurpose applications

- Masonry blades are for cutting tiles

Different brands bring creativity to the game by making specialized blades for more and more specialized applications thereby increasing the types of blades to choose from. You must make the choice on the basis of your requirement i.e. the type of material you are cutting.

If you are interested in learning what are the parameters on the basis of which a blade is said to be best suited for a certain application, there are a limited number of factors,

- As far as material composition of reciprocating saw blade is concerned, almost all reciprocating saw blades are made of steel in which the carbon percentage varies to modify its mechanical properties such as high carbon steel and high speed steel. High speed steel blades are stronger with greater cutting ability but are more expensive than high carbon steel blades. Bimetal blades combine both compositions physically for example teeth will be made of high speed steel whereas body will be made of high carbon steel.

- Blade dimensions (length, height and thickness) also play a role. Harder materials require thicker blades with greater height to give firmness to the blade and prevent it from wobbling or twisting during the cutting operation.

- Cutting teeth profile is a very important factor that mainly covers size, shape and TPI (Teeth Per Inch) of a blade. Blades with higher TPI give slow and smooth cuts whereas blades with low TPI give fast but rough cuts. You might be thinking it is counter intuitive that more teeth cut slow? That is because blades with higher TPI have shorter teeth. In general, blades with higher TPI (12 and above) are used for metals whereas below 12 are used for wood.

- Cutting Tip Composition also plays a very important role. For specialized applications, tips can be of carbide to cut through stronger metals. It is also possible that instead of cutting teeth, there is a carbide grit that refers to strip of carbide pieces best suited for cutting tiles, bricks and masonry. In some rare applications, tips can also be made of diamond to cut through even tougher materials and metals.

If above factors are taken into consideration before buying a reciprocating saw or its blades, we are confident you will make the right choice. We have also written a dedicated article on best reciprocating saws for light to medium duty jobs to get you jump started on your shortlisting.

If you liked this post, please share it with someone who may benefit from it.

Other suggested articles