Explaining the 6 Types of Maintenance Strategies in Industry

Preventive, Reactive, Corrective, Predictive, Proactive & Reliability-Centered Maintenance (RCM)

In today’s post, we will explain 6 different maintenance terminologies and types commonly used in industrial maintenance industry to understand what they are and how they differ from each other.

These maintenance philosophies and strategies include:

- Preventive Maintenance

- Reactive Maintenance

- Corrective Maintenance

- Predictive Maintenance (or Condition-based Maintenance)

- Proactive Maintenance

- Reliability Centered Maintenance

So, let’s not beat about the bush and get straight to explaining them one by one.

Preventive Maintenance

Preventive Maintenance is the maintenance strategy that is based on the philosophy that in order to prevent faults and problems from arising in machines, you have to conduct inspections, checks and part replacements on it periodically.

It includes the inspections, checks, servicing, replacements and any other maintenance activity carried out on a piece of equipment without any fault or problem being experienced in it. Since the purpose of such checks is to prevent faults and problems in equipment, it is called preventive maintenance.

One of the most common preventive maintenance tasks is lubrication. Industrial equipment such as gears, bearings, and motors need to be regularly lubricated to prevent friction and wear. Cleaning and general servicing of parts and components after fixed time intervals is another good example.

Inspections such as checking for any abnormal noise in motors or pumps, checking pressurized lines and its joints for any leaks and checking electrical equipment grounding are some other common examples.

Time-based replacement of parts (such as replacement of an oil filter every 3-months) and run-based replacements (such as replacement of engine oil every 5,000 km) are also classical examples of preventive maintenance activities.

Reactive Maintenance

Reactive Maintenance is all maintenance that is performed as a reaction to trouble. It includes doing corrective maintenance after breakdowns have occurred and performing repair jobs after equipment has experienced hindrance in smooth operation.

In the past, Reactive Maintenance was ‘the maintenance’ in industry. It was common knowledge that maintenance department is there to fix machines when they break down. Today, Reactive Maintenance is discouraged and labelled as old school.

Today, the concept of the job of maintenance department has shifted from ‘fixing problems’ to ‘preventing problems’. Therefore, Reactive Maintenance in today’s age is seen as remains of old school maintenance mindset that needs to be transformed and corrected.

Today, the amount of Reactive Maintenance a department is doing is seen as a measure of its inefficiency and inability to foresee and ‘prevent’ faults.

Corrective Maintenance

Corrective Maintenance is the maintenance performed on equipment to actually fix something as opposed to just inspection or time-based replacement. For example, replacing a bearing because it is giving noise or repairing a faulty compressor to restore the HVAC unit.

An important distinction to be understood in the concept of Corrective Maintenance is how it differs from Reactive Maintenance. Corrective Maintenance work is not necessarily in response to a breakdown. It could quite easily be in response to identification of an issue during Preventive Maintenance or Predictive Maintenance.

For example, the technician found that the pump’s vibration reading is off. The pump is working, it hasn’t failed. However, as a proactive approach, the maintenance team inspects it and finds that its impeller has developed a crack. Replacement of Impeller is a Corrective Maintenance task (although the pump never failed during operation).

Predictive Maintenance (or Condition-based Maintenance)

Predictive Maintenance has become a buzz word in industry since a few years. It is also known as Condition-based Maintenance (CBM). It is a maintenance philosophy and strategy that somewhat challenges the core concept of Preventive Maintenance. This philosophy was developed later than Preventive Maintenance as an evolution in understanding of industrial maintenance.

Where Preventive Maintenance asks to intervene in the machine after a certain time has passed, Predictive Maintenance asks not to. It discourages unnecessary maintenance interventions in the machine.

To elaborate with an example, Predictive Maintenance says that you don’t need to replace engine oil in an industrial generator’s engine after 10,000 running hours. It says you should get a sample of its engine oil tested from a laboratory and replace the oil if the report suggests to do so.

Another example of Predictive maintenance is vibration analysis for rotating machinery such as pumps, motors, and compressors. By measuring the vibration levels of these machines, maintenance teams can identify potential faults or defects in the equipment's components such as bearings, gears, and shafts. Based on the vibration analysis, maintenance teams can then decide on a course of action, such as replacement of parts.

Predictive maintenance utilizes tools and technologies like vibration meters, thermal imagers, ultrasonic leakage detectors and lubricant analysis for predicting future failures by based on data of condition monitoring equipment (tools and technologies we referred).

The concept is ‘do it when needed’ where the ‘needed’ part is ascertained on the basis of condition data as opposed to time or running hours in traditional preventive maintenance. The cue to remember Predictive Maintenance is ‘early warnings’ with reference to seemingly hidden changes in vibration readings or lubricant chemistry that hint towards a future failure.

A question that might cross your mind at this stage is whether there is any difference between Condition-based Maintenance and Predictive Maintenance. The simple answer is that there is no difference in them and both maintenance strategies refer to the same thing i.e., using modern tools and techniques (vibration analysis, oil analysis and thermography etc.) for predicting failures and intervening when necessary.

Proactive Maintenance

There are two variants of the concept of Proactive Maintenance in industry.

The first is simple. Proactive Maintenance is any maintenance work that has been done proactively i.e., not in response to a failure or fault. In this concept, Proactive Maintenance is simply the opposite of Reactive Maintenance.

The second variant of the concept of Proactive Maintenance considers it a maintenance philosophy that addresses the shortcomings of Predictive Maintenance and goes one step further.

In order to clearly understand Proactive Maintenance as per above concept, you need to understand shortcomings present in Predictive Maintenance because Proactive Maintenance is a step further than Predictive Maintenance to answer the shortcomings. There are two shortcomings of Predictive Maintenance in this regard.

The first shortcoming of Predictive Maintenance is that it relies on ‘early warnings’ which can only be given by equipment and components that remain in running condition. Imagine a pressure relief valve that works only when pressure inside a vessel exceeds a certain safe limit.

Majority of the time, the relief valve remains shut. It runs rarely. Neither any ultrasonic sensor not vibration meter can tell if the relief valve has developed some internal problem. You will get to know about it when you don’t want to i.e., the valve won’t work under emergency.

This is where Proactive Maintenance steps in. It says that maintenance team must proactively check for hidden failures in equipment. In the above example, Proactive Maintenance task would be maintenance team checking the relief valve by applying excessive pressure under controlled environment.

The second shortcoming of Predictive Maintenance is that it predicts failure but doesn’t tell you why the abnormality developed in the first place. In short, it doesn’t include Root Cause Analysis of failures.

This is the second area where Proactive Maintenance steps in. It is based on conducting Root Cause Analysis of problems to find why the vibration got out of range in the first place. Maybe the installed ball bearing isn’t rated to withstand the temperatures the machine operates in. So, let’s talk with the engineering team to replace the bearing with a different one (higher temperature rating) so that it doesn’t fail next time.

It may even include going all the way back to suppliers of equipment and revising the specifications of machines and parts you procure from them based on your findings of Root Cause Analysis.

In this way, Proactive Maintenance is all about going beyond the traditional confines of Preventive and Predictive Maintenance to kill issues at their roots with the goal of making the equipment fault-free and maintenance-free.

Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance (RCM) is a maintenance philosophy and strategy that integrates the Preventive, Predictive and Proactive Maintenance strategies to develop not only a maintenance program but an organizational culture and awareness towards maintaining assets.

Reliability Centered Maintenance (RCM) is more a modern maintenance philosophy than it is just a maintenance strategy. The philosophy is focused on the following main concepts:

- Defining functions and performance standards that a company needs from its equipment as opposed to its rated performance from the manufacturer.

- Defining all possibilities of equipment failing to perform its functions as opposed to just focusing on historical failures.

- Developing maintenance strategies that address all possible failures including the ones that may not be experienced historically.

In short, Reliability Centered Maintenance (RCM) is a holistic approach to maintenance that aims to ensure ‘reliable’ operation of equipment over the long term by integrating the Preventive, Predictive, and Proactive Maintenance strategies and driving change in organizational culture and awareness towards maintaining assets.

Final Word

In conclusion, maintenance is constantly evolving with the development of new technologies and philosophies.

Preventive Maintenance is the traditional approach of maintenance that involves regular inspections, checks, servicing, replacements, and other maintenance activities carried out on equipment to prevent faults and problems while Reactive Maintenance is a reaction to breakdowns.

Corrective Maintenance is fixing equipment to restore its functionality while Predictive Maintenance is about using modern technology tools and testing techniques to predict failures based on condition monitoring data.

Proactive maintenance is about Root Cause Analysis and Failure-Finding tasks while Reliability Centered Maintenance (RCM) is a holistic approach combining the best of everything to make equipment more reliable in performing functions that the company needs from it.

Other Articles You May Like

brizy_dc_post_title

Learn about Autonomous Maintenance - part of Total Productive Maintenance that empowers machine operators in basic maintenance tasks.

brizy_dc_post_title

Learn what is RAMS - acronym of Reliability, Availability, Maintainability & Safety/Supportability - in industrial maintenance.

brizy_dc_post_title

We explain what is the supposed role of Maintenance Planning Department in industry. We clear misconceptions and give do's and don'ts.

brizy_dc_post_title

Explaining 6 industrial maintenance types: Preventive, Reactive, Corrective, Predictive, Proactive and Reliability Centered Maintenance.

brizy_dc_post_title

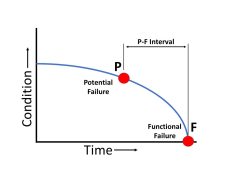

Practical aspects of PF Curve and PF Interval in maintenance & reliability explained. Learn what's the most important question in PF interval?

brizy_dc_post_title

The practical application of ABC classification of inventory for maintenance spare parts with examples from different industries.

brizy_dc_post_title

We explain the concept of Inherent Reliability - A metric used in industrial maintenance and reliability management.

brizy_dc_post_title

Intuitive explanation of Achieved Availability - Metric used in Industrial Maintenance & Reliability Management.

brizy_dc_post_title

Explaining in simple English the term Mean Time To Repair or Replace (MTTR) used in maintenance management.

brizy_dc_post_title

We explain the terms Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) in simple and practical language.

brizy_dc_post_title

We give a detailed example of calculating Overall Equipment Effectiveness (OEE) for HVAC equipment (in a story telling style).

brizy_dc_post_title

Explaining the 8 wastes of lean manufacturing (or lean production) philosophy that are applicable on maintenance management.

brizy_dc_post_title

Intuitive explanation of the difference between Total Effective Equipment Performance (TEEP) & Overall Equipment Effectiveness (OEE).

brizy_dc_post_title

We explain in layman terms what is Overall Equipment Effectiveness (OEE) - a metric maintenance teams aim to maximize in industry.

brizy_dc_post_title

We explain a useful metric that is used by maintenance managers to determine efficiency of their maintenance workforce.

brizy_dc_post_title

We explain the maintenance work order system (or work management system) used by maintenance departments in simple words.