Maintenance Management

Vision vs. Mission Statement – Anatomy & Key Differences [Emphasis on Engineering & Manufacturing Businesses]

We explain the anatomy and the differences in vision vs. mission statement of manufacturing and engineering businesses.

Unutilized Talent in Maintenance Organizations – A Waste in Lean Manufacturing Philosophy

We discuss how unutilized talent of maintenance personnel is a waste to be avoided in maintenance management.

Maintenance Work Order System (or Work Management System) Explained [FOR NOOBS]

We explain the maintenance work order system (or work management system) used by maintenance departments in simple words.

How Much Maintenance Manpower Does an Efficient Plant Need? – Ratio of RAV to Craft-wage Headcount: A Useful Metric to Understand

We explain a useful metric that is used by maintenance managers to determine efficiency of their maintenance workforce.

Layman Explanation of Overall Equipment Effectiveness (OEE)

We explain in layman terms what is Overall Equipment Effectiveness (OEE) - a metric maintenance teams aim to maximize in industry.

Total Effective Equipment Performance (TEEP) vs. Overall Equipment Effectiveness (OEE) – The Difference Decoded

Intuitive explanation of the difference between Total Effective Equipment Performance (TEEP) & Overall Equipment Effectiveness (OEE).

The 8 Wastes of Lean Maintenance Management – Applying Lean Manufacturing (or Lean Production) Philosophy to Maintenance

Explaining the 8 wastes of lean manufacturing (or lean production) philosophy that are applicable on maintenance management.

Example Calculation of Overall Equipment Effectiveness (OEE) – How to Calculate OEE? – Explained with Storytelling

We give a detailed example of calculating Overall Equipment Effectiveness (OEE) for HVAC equipment (in a story telling style).

MTBF & MTTF – Simple English Explanation

We explain the terms Mean Time Between Failures (MTBF) and Mean Time To Failure (MTTF) in simple and practical language.

Layman Explanation of MTTR (Mean Time To Repair or Replace)

Explaining in simple English the term Mean Time To Repair or Replace (MTTR) used in maintenance management.

What is Achieved Availability in Maintenance & Reliability? – Intuitive Explanation with Example Calculation

Intuitive explanation of Achieved Availability - Metric used in Industrial Maintenance & Reliability Management.

What is Inherent Availability in Maintenance & Reliability? – Clarifying Misconceptions & Addressing Knowledge Gaps

We explain the concept of Inherent Reliability - A metric used in industrial maintenance and reliability management.

Understanding ABC Classification of Inventory for Maintenance Spare Parts: Examples from Different Industries

The practical application of ABC classification of inventory for maintenance spare parts with examples from different industries.

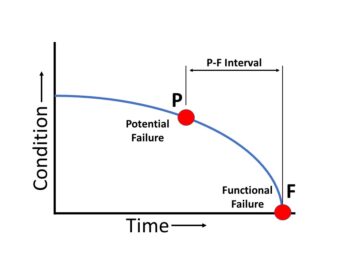

The Practical Aspects of P-F Curve and P-F Interval in Maintenance & Reliability

Practical aspects of PF Curve and PF Interval in maintenance & reliability explained. Learn what's the most important question in PF interval?

The 6 Types of Maintenance: Preventive, Reactive, Corrective, Predictive, Proactive & Reliability-Centered Maintenance – Simple Explanation

Explaining 6 industrial maintenance types: Preventive, Reactive, Corrective, Predictive, Proactive and Reliability Centered Maintenance.

The Intended Role of Maintenance Planner in Industry

We explain what is the supposed role of Maintenance Planning Department in industry. We clear misconceptions and give do's and don'ts.

RAMS [Reliability, Availability, Maintainability, Safety / Supportability] – What is it? How It’s Done? & What’s its Purpose?

Learn what is RAMS - acronym of Reliability, Availability, Maintainability & Safety/Supportability - in industrial maintenance.

Autonomous Maintenance (Jishu Hozen) – Simple Explanation

Learn about Autonomous Maintenance - part of Total Productive Maintenance that empowers machine operators in basic maintenance tasks.